Welcome to the deep dive. Today we're going to be looking at something, I have to admit, I never thought much about before. Injection mold draft angles. You sent over some fascinating articles, though, and yeah, it's like those tiny details that you don't realize are a big deal, right?

Yeah, totally. It's one of those things that's kind of hidden, plain sight. Like you don't really think about it until you start looking into it. But then you realize, wow, these tiny angles actually make a huge difference in how smoothly things get made.

Okay, so I have a confession to make. I'm actually a little fuzzy on what a draft angle even is. Could you break it down for us? Like, explain it to me like I'm five.

Okay. Imagine you're trying to get a cake out of a pan. If the sides were straight up and down, the cake would probably get stuck, right?

Yeah, definitely.

But if you have a slight slope to the sides, the cake slides right out.

Oh, okay.

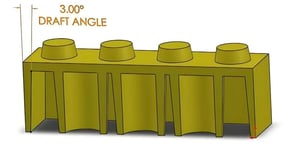

That slope is the draft angle. And it's the same idea with injection molding. That slight angle lets the part come out of the mold cleanly.

So it's like a built in escape route for the plastic.

Exactly. And those escape routes, those draft angles, are crucial for mass production. Without them, things would get really messy and expensive.

That makes a lot of sense. So speaking of making things smoothly, our sources mention something called ISO standards for draft angles. What are those all about?

So ISO standards are these international guidelines. They're basically like a set of best practices to help make sure things are manufactured consistently no matter where in the world you are.

Right. Makes sense.

For plastics, the general ISO standard recommends a draft angle of, see, 0.5 to 1.5 degrees for the outer surfaces.

The outer surfaces meaning like the parts you see and touch?

Exactly. But the inner surfaces think like the inside of a bottle or a container. They actually need a steeper angle.

Oh, why is that?

Well, because the inner surfaces tend to cling to the mold more tightly. So you need that extra degree or two angle to make sure they release cleanly. Usually it's somewhere between 1 and 3 degrees.

Okay, that makes sense. It's a kind of like, it's harder to pull a sock off if it's inside out.

Yeah, that's a good analogy.

So we've got these ISO standards, which are like the global guidelines. But then our sources also talk about something called VDA standards, specifically for the automotive industry. Why do cars need their own separate set of standards?

Well, the automotive industry is all about precision. I mean, think about all the parts in a car, they all have to fit together perfectly. And on top of that, they have to be able to withstand all sorts of stress, like vibrations and temperature changes.

Right.

So to make sure everything works flawlessly, the automotive industry has its own set of standards which are even more demanding than the ISO standards. These are the VDA standards. It stands for Verband der Automobile Industry, which is German for Association of the Automotive Industry.

Ah, okay, that makes more sense. So what kind of angles are we talking about for cars then?

Well, for outer surfaces it's 1 to 2 degrees, and for inner surfaces it's 2 to 4 degrees.

So even stricter than those ISO standards.

Yeah, and I know it might not seem like a big difference, but in the automotive world, those fractions of a degree can really make a difference.

Wow, you're right. I never would have guessed that. So much thought goes into something like the dashboard of my car. It's amazing how much we take for granted, you know?

Absolutely. There's a whole hidden world of precision engineering behind all the stuff we use every day.

Yeah. And it's not just about following those ISO and VDA standards either. Right. Because our sources talk about how companies often create their own internal standards on top of all that.

Right. And that's where things get really interesting, because it's all about finding that balance between meeting industry requirements and going above and beyond to achieve their own specific goals.

So it's like they're building their own mini ecosystem of perfectly angled parts. I mean, can you give us an example of how this works in the real world?

Sure. So let's say you've got a big company that makes appliances like refrigerators, washing machines, that kind of thing.

Okay. Yeah.

And they're known for making really durable, sleek looking products.

Right.

Well, to maintain that reputation, they might decide that they're going to require a minimum 1 degree draft angle on all the outer surfaces of their appliances.

Okay. Even if the ISO standard allows for a slightly shallower angle.

Exactly.

So they're being even stricter than the international guidelines.

Right. And there are a few reasons why they might do that. Maybe they found that a slightly steeper angle actually makes their products more durable, you know, less likely to crack or warp over time.

Oh, interesting.

Or maybe it helps them achieve a specific kind of surface finish that's become part of their brand identity. It could be lots of things. But the point is, large companies often have huge product lines and those internal standards help them maintain consistency across everything they make.

I can see how that would be important. So what about Smaller companies then, do they do the whole internal standards thing too?

They do, but smaller companies tend to be a bit more flexible. They often adapt those industry standards to fit their specific equipment and the materials they're using. And sometimes that adaptability actually gives them a competitive edge, like it lets them specialize in niche markets or try out new approaches that might be harder for a larger company to do.

So it's like they're becoming masters of their own little corner of the manufacturing world.

Exactly. They're fine tuning those angles to perfectly suit their needs.

It's fascinating how something as simple as a draft angle can have such a big impact on, well, everything. But with all these different standards floating around, international ones, industry specific ones, company specific ones, doesn't that create a potential for chaos? Like, how does all of this affect the actual quality of the products we use every day?

That is a fantastic question. And that's exactly what we're going to dig into after a quick break.

So before the break, we were talking about all these different standards for draft angles. It's fascinating, but I also have to wonder what happens when things go wrong? What are the consequences of messing up those angles?

Well, one of the biggest risks is manufacturing defects. Like, if the draft angle is too shallow, the part can get stuck in the mold, and that can cause all sorts of problems.

Like what?

You could end up with warping where the part comes out kind of misshapen. Or you might get surface damage, like scratches and dents. And worst case scenario, the part could even break when they're trying to get it out of the mold.

Ouch. Yeah, I can imagine that would be a costly mistake.

Definitely.

And it's not just about problems during manufacturing. Right. Because most parts have to work with other parts, right?

Exactly. And if the draft angles aren't consistent across all those different components, it might not fit together properly.

So it's like trying to fit a square peg into a round hole.

Yeah, pretty much, yeah. And that can lead to. Well, it can mess up the whole assembly line, slow things down, make the product perform poorly, and in some cases, it can even create safety hazards if parts aren't connected securely.

Yeah, that makes sense. And speaking of hazards, our sources actually mention product recalls as a potential consequence of inconsistent draft angles. That sounds pretty serious.

Yeah, it is. Serious product recalls are a nightmare for any company. I bet they cost a ton of money. They damage the brand's reputation, and sometimes they can even lead to legal issues.

So those tiny angles really can have huge consequences.

Absolutely. Inconsistent draft angles can definitely contribute to Recalls, especially if they lead to parts that break easily or that pose a safety risk.

It's kind of scary to think about, but I guess that's why companies put so much effort into those internal standards. Right. They're trying to head off those problems before they happen.

Exactly, exactly. Companies invest a ton of time and resources into developing their own internal standards because they know that consistency is key. It's how they make sure their products are high quality and that everything runs smoothly. So by setting these really strict guidelines that go above and beyond those basic industry standards, they're creating more control over their whole manufacturing process.

Right, but you mentioned earlier that there can also be downsides to having those super strict internal standards. Something about compatibility issues. Right?

Yeah. So imagine you've got this company that makes, I don't know, car engines, okay. And they have these insanely strict internal standards for their draft angles. And everything sits together perfectly. The engines perform amazingly. They're top of the line engines.

Right.

But then what happens if those engines need to be used in a vehicle made by a different company? A company that uses, you know, more relaxed standards?

Oh, I see what you're saying. You could end up with the situation where the engine, even though it's a great engine, doesn't actually fit in the car properly.

Exactly. Or maybe some of the other components don't connect with the engine the way they should because the angles don't match up.

So you've got this amazing engine that's basically useless.

Yeah, pretty much. And that's why communication and collaboration are so important. When everyone in an industry is on the same page about standards, things tend to go a lot more smoothly. But when companies go off and create their own crazy strict standards, it can cause these compatibility headaches.

So it's a balancing act. Companies want to make the best products they can, but they also have to think about how those products are going to interact with the rest of the world. I guess that's where organizations like ISO come in. Right. They're trying to create a common language for everyone.

That's a great way to put it. Organizations like ISO are crucial because they set those baseline standards that ensure a certain level of, like, consistency. It makes sure things are interoperable, which means they'll work together. But it's not about squashing innovation. It's more about creating a framework that lets innovation happen safely and efficiently.

This is also interesting. I really had no clue how much strategy goes into something like a draft angle. It's not all about potential downsides and compatibility problems though, right? You said earlier that sometimes those variations in standards can actually lead to innovation. I'm curious to hear more about that.

Yeah, absolutely. And that's exactly what we're going to explore after a quick break.

All right, so we're back and ready to wrap up our deep dive into injection mold draft angles. Before the break, we were talking about how these tiny little angles can actually lead to big innovations. And I have to admit, I'm still a little confused. I mean, how can a rule about getting a part out of a mold spark something totally new and groundbreaking?

Well, think of it this way. Sometimes the most creative solutions come from really pushing the boundaries of what's considered, you know, standard. A company that really knows its stuff when it comes to those internal standards. A company that understands exactly how even like a fraction of a degree can change a part's performance. They can come up with designs that you just would be able to make with those more generic guidelines.

So they're using those precise angles as, like, a design tool, not just a rule they have to follow.

Yeah, exactly. It's almost like, you know, how a sculptor can chisel away tiny bits of stone to create something amazing? Yeah, it's kind of like that. The engineer is the sculptor, and the draft angles are their chisel. They're not just shaping the part itself, but how it works and how it looks.

I like that. That really helps me picture it. So do you have any, like, real world examples of how this plays out?

Think about smartphones. Like, remember those early smartphones? They were clunky and thick.

Yeah, I remember.

But as manufacturers got better at injection molding and really learned to control those draft angles, they were able to make those phones thinner and sleeker. And that's how we got to the phones we have today.

Oh, wow. I never thought about it like that, but you're right. So those tiny angles literally helped make my phone pocket friendly.

Exactly. And it's not just smartphones. It's all sorts of things.

Yeah, like what?

Think about specialized products, like those custom made parts for medical devices or high performance sporting goods for those products. Sticking to those general standards might actually limit what you can do. But if you have the flexibility to tweak those angles, you can create some really amazing things.

So it's about finding that sweet spot. You need those baseline standards, but you also need the freedom to experiment and push the limits.

Right. You gotta know the rules so well that you can bend them in a way that makes something really special. Wow.

You know, I'm looking at all the plastic stuff around me. My phone, that water bottle over there, even my kids toys. And it's like I'm seeing them in a whole new light.

It is pretty cool when you think about it. Those hidden angles are a reminder of how creative and ingenious people can be.

Well, on that note, I think we've reached the end of our deep dive into the world of injection mold giraffe angles.

Yeah, time flies when you're having fun exploring tiny angles.

It really does. And I gotta say, I'm walking away with a newfound appreciation for all those little details that make the world work.

Me too. And who knows what other amazing things those angles will lead to in the future.

Exactly. Well, thanks for joining me on this deep dive. And to everyone listening, be sure to join us next time for another fascinating look at something you might not have thought much about