All right, so today, let's talk injection molding. Okay, I know, I know. Not exactly the most, you know, exciting topic at first glance.

Right.

But trust me, this deep dive is going to change the way you think about, you know, all those everyday plastic products, like, surrounding us.

Yeah.

We're taking a look at this article titled how do Long Cooling times affect Injection Molds?

Interesting.

And I have to say, the author is seriously passionate about this stuff.

Oh, wow.

So get ready to learn why cooling times are like the unsung heroes or villains of the entire, you know, manufacturing game.

You hit the nail on the head, really. Tooling times are often overlooked, but they have a ripple effect that impacts everything from a product's quality to a company's bottom line.

Oh, wow.

To. Yes. Even your online order arriving on time.

Okay, so the article really stresses this idea of a domino effect. They gave an example of a production line.

Yeah.

Going from five units per minute down to three.

Right.

Simply because of longer cooling times. That's a huge drop.

Yeah.

But honestly, beyond the slower pace, like, what's the big deal? Well, with a few extra seconds here and there.

Think about it this way. Every second a machine is tied up cooling apart.

Okay.

Because the second it's not producing another one.

Right.

In high volume manufacturing.

Yeah.

Those seconds add up quickly.

Oh, I see.

Impacting efficiency and profitability in a big way. We're not talking about a few pennies here. No, longer cooling times can translate to thousands, even millions of dollars in lost revenue for companies.

Wow.

And on a broader scale, it can even influence market competitiveness.

Oh, really?

If one company can produce twice as fast due to optimized cooling.

Right.

They have a significant advantage.

Now that you put it that way, it makes total sense. Yeah, it's like rush hour traffic for injection molding machines.

Exactly.

Everything gets backed up and nobody's going anywhere fast.

And the impact goes beyond just speed.

Oh, okay.

The article digs into how those longer cooling times can seriously mess with the quality of the product itself.

The article talked about a whole laundry list of problems. Dimensional accuracy was one of them. Okay, I'm guessing we're not talking about a tiny, unnoticeable shrinkage here.

Not always. You see, when a part cools too slowly, okay. It can shrink unevenly, leading to dimensional inaccuracies that can make assembly a nightmare.

Wow.

Imagine trying to fit together pieces of a puzzle where the edges don't quite align.

Right.

It's frustrating and time consuming.

Yeah.

In some cases, it can even render the entire product unusable.

So Basically a manufacturing headache of epic proportions.

Pretty much.

And this is just one issue.

Yeah.

Caused by those pesky extended cooling times.

Right.

The article also mentioned war pitch.

Yes.

Is that as bad as it sounds?

It can be, especially with large or thin parts.

Oh, really?

Uneven cooling causes stresses within the material, leading twisting and bending.

I see.

Think about a phone case, for example.

Okay.

If it warps during cooling, it won't fit properly, the buttons might not align, and it could even crack. Not exactly the sleek, functional product designers had in mind.

And then to add insult to injury. Yeah, there are those dreaded surface defects.

Right.

I'm picturing blemishes, bumps, anything that ruins the look and feel of the product.

Precisely. The article specifically mentioned cold marks and flow lines as common culprits.

Ah.

These imperfections can be a major problem, particularly for products where aesthetics are key, like electronics. Or anything with a high gloss finish.

Right.

Imagine unboxing a brand new laptop only to find unsightly blemishes on the casing.

Yeah.

It immediately diminishes the perceived quality and can be a major turn off for consumers.

It seems like everything that can go wrong does go wrong when those cooling times get out of hand.

Definitely.

But wait, there's more.

What?

The article also pointed out that those extended cooling times can actually damage the molds themselves.

That's right. It's an often overlooked consequence.

Wow.

But it can be incredibly costly. We're talking about potential damage that can significantly shorten the lifespan of these expensive molds.

Okay.

The constant heating and cooling cycles cause stress, leading to micro cracks that weaken the mold over time.

Right.

Think of it like bending a paperclip back and forth repeatedly.

Yeah.

Eventually it's gonna snap.

Ok. Okay. So we've established that long cooling times are the enemy.

Right.

But what about the mold itself?

Okay.

Does the material it's made of play a role in all of this?

Absolutely. The mold material's thermal properties.

Okay.

Directly influence how quickly and evenly it can transfer heat away from the molten plastic. Some materials are naturally better conductors than others, allowing for faster and more uniform cooling.

So choosing the right mold material is like picking the right pan for cooking.

Yes.

You wouldn't bake a cake in a cast iron skillet, would you?

That's a great analogy.

Thanks.

Different materials are suited for different tasks.

Right.

And understanding the thermal properties of mold.

Materials is crucial for optimizing cooling times and ensuring consistent product quality.

So we've covered a lot of ground here. We have the domino effect of slower production, the impact on product quality, even the damage to the molds themselves. It's clear that cooling times are a critical factor in the injection molding.

Absolutely.

But I'm curious. What about those companies who might be thinking, hey, maybe those longer cooling times aren't so bad.

Yeah.

Especially if we're not in a rush.

Right.

Could there ever be a scenario where they're actually beneficial?

That's a great question and one that challenges conventional thinking.

Okay.

While the article focuses heavily on the downsides of extended cooling times.

Right.

It does raise an interesting point.

Okay.

Could there be hidden advantages in specific situations? It's certainly something worth exploring further.

Okay. I'm intrigued. Let's dig into that. Okay, I'm intrigued. Let's dig into that.

Right.

So before, we were talking about, like, the potential upsides of longer cooling times.

Which seems a bit counterintuitive considering all the problems we just discussed.

Right.

I'm ready to have my mind blown here.

Okay.

What are we missing?

Well, it's all about context.

Okay.

And understanding the nuances of the process.

Right.

For example, imagine a scenario.

Yeah.

Where you're working with with a material that's prone to, like, stress cracking if cooled too quickly.

Okay.

In that case, a longer, more gradual cooling process might actually be beneficial to prevent those defects.

So it's like tempering chocolate.

Exactly.

We have to cool it slowly and carefully to achieve that perfect snap and shine. Rush it, and you end up with a dull, crumbly mess.

It's about finding the sweet spot for each material and application.

Okay.

Another area where longer cooling times might play a role is in achieving specific material properties.

Oh, really?

Some materials might actually benefit from a prolonged cooling process to develop desired characteristics like increased crystallinity or improved impact resistance.

So it's not always about speed.

Right.

Sometimes taking things slow and steady can actually lead to a better outcome.

Exactly.

But I'm guessing that most manufacturers are still aiming to optimize those cooling times. Yes, as much as possible.

Of course.

What kind of strategies are we talking about here?

Well, the article highlights a few key.

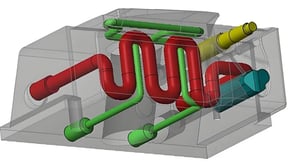

Areas, Ensuring that the cooling is consistent across the entire surface.

That makes a lot of sense.

It's like giving the mold a custom fitted cooling system.

Yes.

Rather than a one size fits all approach.

Right.

But even with the best mold design, sometimes you need a little extra firepower, right?

Absolutely. And that's where advanced cooling technologies come in.

Okay.

The article mentioned techniques like high pressure air cooling and even liquid nitrogen cooling.

Wow.

These methods can dramatically reduce cooling times without sacrificing surface quality.

Okay. Now we're talking Serious cooling power.

Yeah.

Break down the science for me here. How does high pressure air actually speed up the cooling process?

Think about it this way. When you blow on something hot, it cools down faster.

Right.

The same principle applies here, but on a much larger scale.

Okay.

High pressure air is directed under the surface of the molded part, increasing the rate of heat transfer and significantly reducing cooling times.

So we've got fancy molds.

Yeah.

High tech cooling methods. What else can manufacturers do to get those cooling times in check?

Well, the article also touched on the importance of process optimization software.

Okay.

These sophisticated systems use real time data and algorithms.

Right.

To constantly monitor and adjust the cooling process, ensuring that everything is running at peak efficiency.

So it's like having a digital brain overseeing the entire operation, pretty much making those tiny tweaks and adjustments that a human operator might miss.

Precisely. These software systems can analyze data from sensors embedded within the mold.

Wow.

Tracking temperature variations, cooling rates, and other critical parameters. They can then automatically adjust cooling parameters like coolant flow rate and temperature to maintain optimal conditions throughout the cycle. Right. This level of precision and control can significantly reduce cooling times while ensuring consistent product quality.

Okay, so we've covered a lot of ground here.

Yes.

Advanced mold designs, high tech cooling methods, even software that acts like a virtual conductor.

Right.

But surely the material itself plays a role. Right.

You're absolutely right.

Could choosing a different type of plastic actually speed up the process?

The article emphasized the importance of smart material choices when it comes to optimizing cooling times.

Right.

Some plastics have higher thermal conductivity than others, meaning they can transfer heat away more quickly.

I see.

By selecting materials with faster cooling properties.

Yeah.

Manufacturers can shave off valuable seconds or even minutes from the overall cycle time.

So it's like choosing the right fabric for your workout clothes.

Exactly.

Some materials are just better at wicking away moisture and keeping you cool.

Yes.

Pick the wrong one, and you're in for a sweaty, uncomfortable experience.

It's about understanding the inherent properties of the materials.

Okay.

And how they influence the cooling process.

Right.

And speaking of maintaining optimal conditions. Yeah. There's another crucial aspect the article highlighted. Diligent maintenance.

Okay. This one might not sound as exciting as liquid nitrogen cooling.

Right.

But I have a feeling it's just as important.

Oh, it is.

What does diligent maintenance entail in the world of injection molding? Okay, I get it. Keeping things clean and running smoothly is always a good idea.

Right.

But how does that specifically relate to cooling times?

Well, think about the cooling channels within the mold.

Okay.

Over time, these channels can become clogged with mineral deposits, rust, or even bits of plastic. Wow. This buildup restricts coolant flow.

Right.

Reducing cooling efficiency and ultimately extending those cooling times.

So it's like neglecting to clean your gutters. Yeah. Eventually, the water can't flow freely.

Exactly.

And you end up with a big, messy problem.

Precisely.

Right.

Regular maintenance, including cleaning and inspecting those cooling channels, Is essential to prevent these issues.

Right.

And ensure that the cooling system operates at peak performance. It also involves monitoring coolant quality.

Okay.

Checking for contamination.

Right.

And making sure that pumps and other components are functioning properly.

All right, so to sum it all up, We've gone from thinking about cooling times as just a few extra seconds to realizing there are this intricate, crucial factor that influences everything.

It really does.

From production speed and efficiency to product quality, Quality, and even the longevity of the molds themselves.

It's a hidden world.

It's like this hidden world within manufacturing that most of us never even consider.

I completely agree.

Yeah.

And I think what's particularly interesting Is that this deep dive into cooling times has challenged some of those traditional assumptions.

Right.

We often think about faster as always being better.

Yeah.

But as we've discussed, There are situations where a slower, more controlled cooling process Might actually be the key to achieving optimal results. Results.

It's all about understanding the nuances. The interplay between materials, processes, and desired outcomes.

Exactly.

There's no one size fits all solution.

Nope.

It's about adapting and fine tuning those cooling times to match the specific needs of each product and application.

Exactly. And as technology continues to evolve, we're likely to see even more innovative approaches to cooling.

Wow.

Pushing the boundaries of what's possible in injection molding.

So, dear listener, the next time you pick up a plastic product.

Yeah.

Take a moment to appreciate the journey it took to get there. The carefully calculated cooling times, the intricate mold designs, and the constant pursuit of optimization.

It's pretty amazing.

It's a testament to human ingenuity and the relentless drive to improve and innovate.

And who knows? Maybe you'll be inspired to explore those unconventional approaches.

Yeah.

To find those hidden advantages in the most unexpected places.

Right.

After all, the world of injection.

Yeah.

Much like those cooling times, it's full of