MANUFACTURING

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Key Factors to Consider When Choosing Mold Processing Technology?

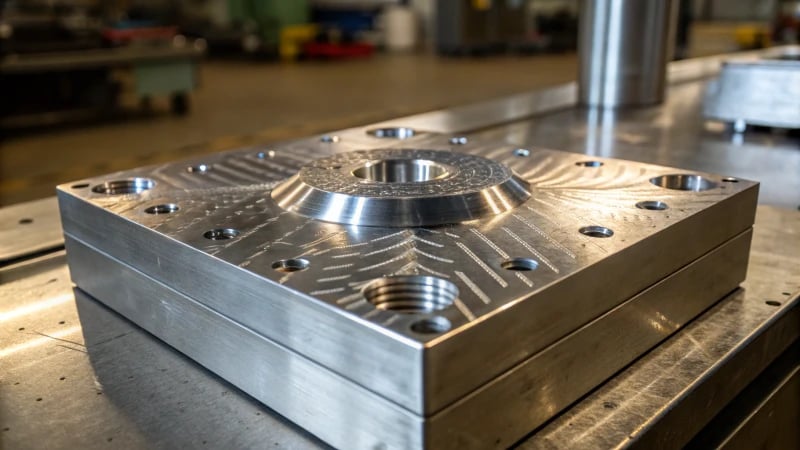

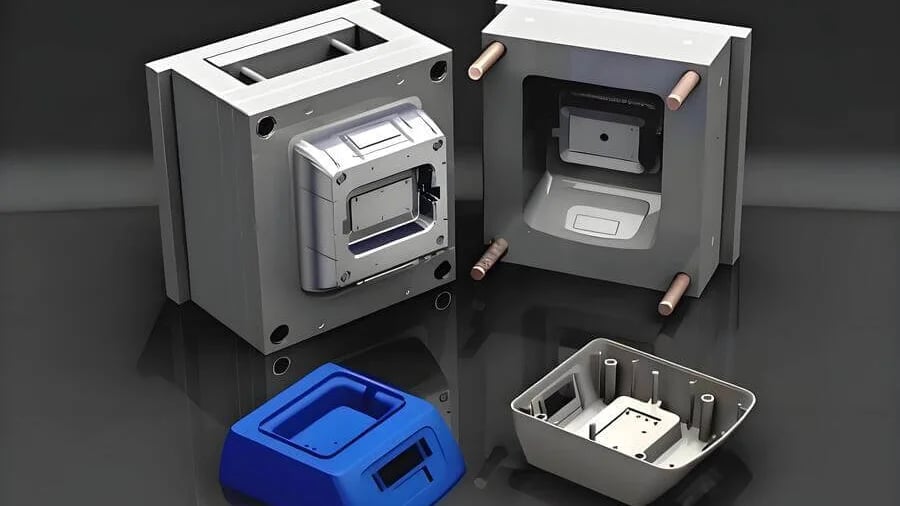

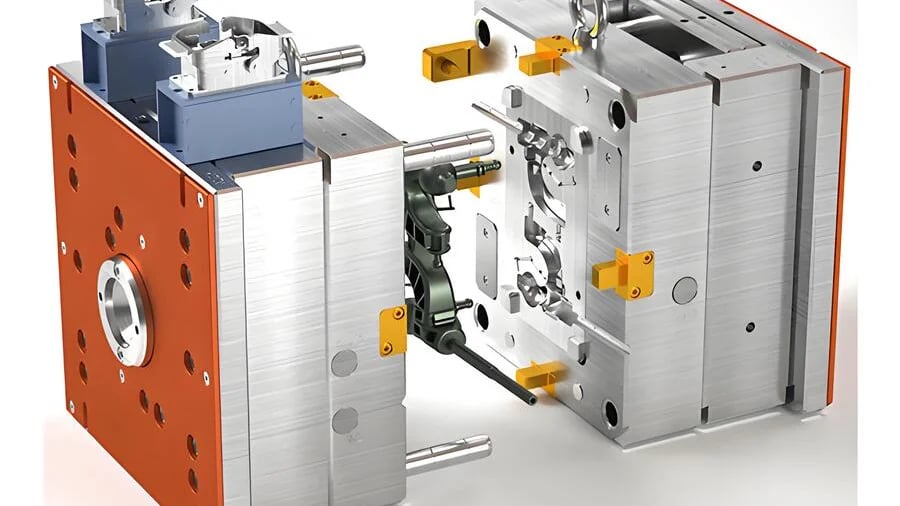

Selecting the right mold processing technology is crucial for high-quality production. Key factors include design complexity, material characteristics, production quantity, equipment capabilities, technician expertise, and budget limits. Complex designs often require advanced techniques like high-speed milling or EDM for precision. ...

MANUFACTURING

What Are the Best Methods for Determining the Processing Technology of Complex Cavity Shape Molds?

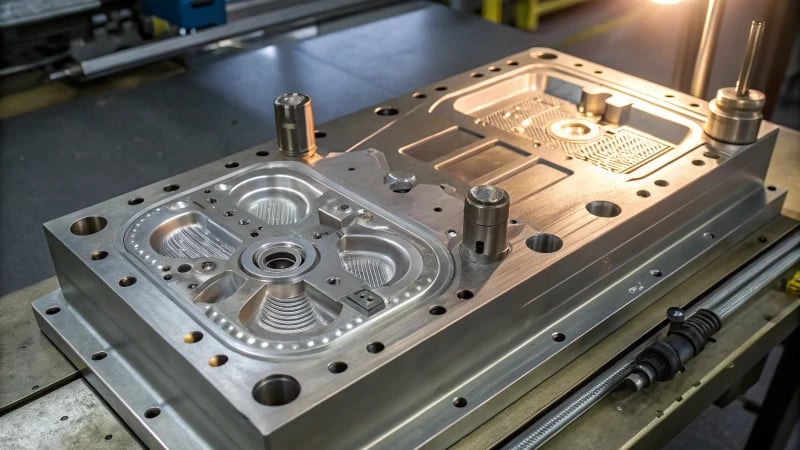

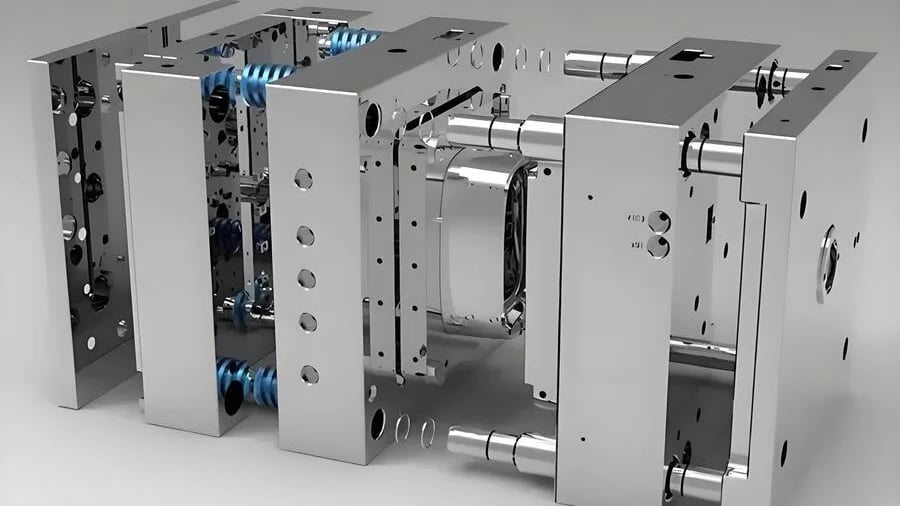

Determining the best processing technology for complex cavity shape molds involves analyzing cavity characteristics such as surface type and internal structure. High-speed milling (HSM) is ideal for free-form surfaces, while Electrical Discharge Machining (EDM) excels in intricate designs. Material properties ...

MANUFACTURING

What Are the Key Considerations for Programming and Preparing Molds with Complex Cavity Shapes?

This article explores essential considerations for programming and preparing molds with complex cavity shapes. It emphasizes the importance of detailed shape analysis, effective tool path planning, appropriate cutting parameters, and selecting suitable CAD/CAM software. Additionally, it discusses the significance of ...

MANUFACTURING

What Is the Best Tool for Processing Molds with Complex Cavity Shapes?

Choosing the right tools for processing molds with complex cavity shapes is crucial for achieving precision and quality. This article discusses various milling cutters like ball-end, end, forming, and micro-diameter tools. It highlights the significance of selecting appropriate materials such ...

MANUFACTURING

How Does Mold Steel Hardness and Toughness Affect Injection Mold Precision?

This article explores the critical roles of hardness and toughness in injection molds. Hardness affects dimensional stability and surface quality, while toughness prevents fractures under pressure. High-hardness steels like H13 maintain cavity size for precise products, while tough steels like ...

MANUFACTURING

How Do Different Surface Treatments Impact the Wear Resistance of Injection Molded Plastic Products?

This article explores how various surface treatments impact the wear resistance of injection molded plastic products. Techniques such as spraying, electroplating, thermal transfer, silk screen printing, laser marking, frosting, and polishing each offer distinct advantages and challenges. Spraying enhances durability ...

MANUFACTURING

Which Mold Material Can Enhance the Precision of Your Injection Molding?

Selecting the appropriate mold material is essential for achieving precision in injection molding. Factors such as production batch size, required accuracy, and working environment significantly influence this choice. For small batches, P20 steel offers cost-effectiveness and reliability. In contrast, H13 ...

MANUFACTURING

How Can You Adjust Injection Molding Parameters to Prevent Mold Underfilling?

This article discusses how to adjust injection molding parameters to prevent mold underfilling. Key strategies include gradually increasing injection speed, optimizing pressure settings, and accurately calculating injection volume. By understanding these factors, manufacturers can improve product quality and reduce defects ...

MANUFACTURING

How Does Injection Pressure Influence the Dimensional Accuracy of Injection Molded Products?

This article explores how injection pressure impacts the dimensional accuracy of molded products. High injection pressure can lead to larger sizes and internal stresses, resulting in warping and instability. Conversely, low injection pressure may cause incomplete mold filling, leading to ...

MANUFACTURING

How Can You Enhance the Surface Treatment Quality of Injection Molded Plastic Products?

This article explores how to improve the surface treatment quality of injection molded plastic products through careful design considerations, material selection, and precise control of the injection molding process. It emphasizes the importance of avoiding sharp corners and complex shapes ...

MANUFACTURING

What is the Best Surface Treatment for Injection Molded Plastic Products?

Selecting the right surface treatment for injection molded plastic products is crucial for achieving optimal functionality and aesthetic appeal. Factors such as abrasion resistance, corrosion protection, electrical insulation, and optical clarity must be considered. Techniques like spraying enhance wear resistance ...

MANUFACTURING

How Do You Set the Injection Pressure in an Injection Molding Machine?

This article explores the complexities of setting injection pressure in molding processes. It emphasizes the importance of considering product shape, material properties, and mold performance to achieve optimal results. Proper pressure settings are essential for ensuring complete filling of molds ...

MANUFACTURING

Why Does Mold Underfilling Occur and How Can It Be Prevented?

Mold underfilling is a common issue in injection molding where the plastic does not completely fill the mold. This can result from various factors such as slow injection speeds, low pressure, poor mold design, and material properties like viscosity and ...

MANUFACTURING

How Does High Injection Pressure Cause Defects in Products?

High injection pressure during plastic molding can cause significant defects such as flying edges, stream marks, and burn marks. These flaws not only detract from the aesthetic quality of products but also weaken their structural integrity. Excessive pressure results in ...

MANUFACTURING

How Does Mold Temperature Affect Warpage and Deformation in Injection Molded Products?

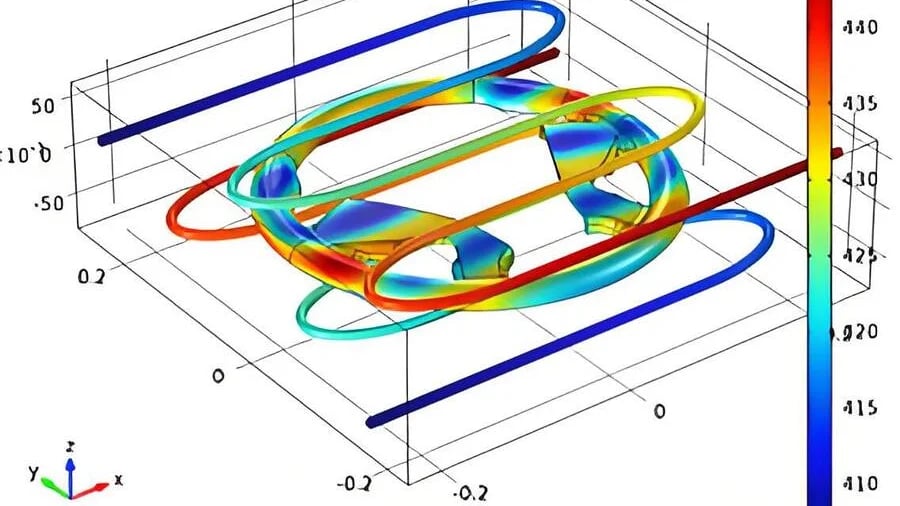

This article explores how mold temperature affects warpage and deformation in injection molded products. High mold temperatures slow cooling, causing thermal stress and uneven crystallization, while low temperatures lead to rapid cooling that traps internal stresses. Both scenarios can result ...

MANUFACTURING

How Does Hardness Affect the Wear Resistance of Mold Materials?

This article explores the relationship between hardness and wear resistance in mold materials. It emphasizes that while higher hardness generally improves wear resistance, factors like toughness, microstructure, and environmental conditions play critical roles. Designers must balance these elements to enhance ...

MANUFACTURING

What Impact Does Mold Temperature Have on the Dimensional Accuracy of Injection Molded Products?

Mold temperature is crucial in injection molding, affecting product dimensions and quality. High temperatures can lead to larger sizes due to reduced shrinkage and enhanced crystallinity, while low temperatures may cause uneven cooling, resulting in smaller dimensions and defects. Understanding ...

MANUFACTURING

How Is the Standard Development Process for Injection Molds Defined?

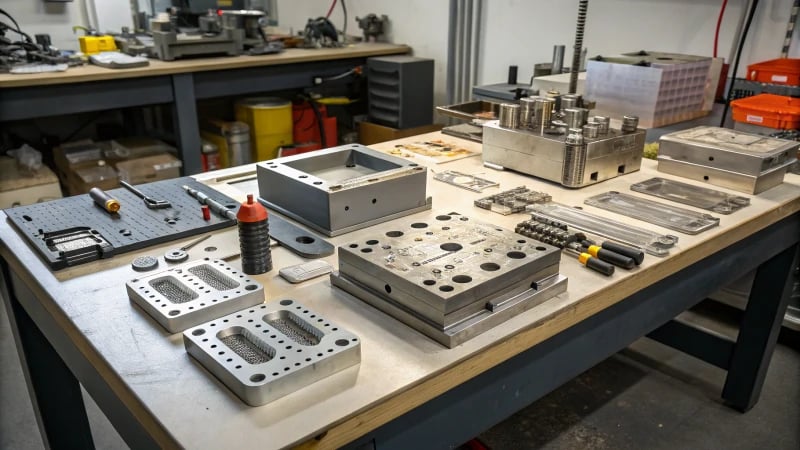

This article outlines the standard development process for injection molds, detailing essential steps such as product analysis, design planning, mold structure considerations, manufacturing techniques, trial testing procedures, and the importance of data organization. Each phase is crucial for ensuring high-quality ...

MANUFACTURING

How Does Injection Speed Affect the Productivity of Injection Molds?

This article explores the critical role of injection speed in the productivity of injection molds. It highlights how adjusting injection speed can reduce cycle times, enhance product quality, and improve demolding efficiency. However, it also addresses the potential risks associated ...

MANUFACTURING

How Quickly Can Injection Molds Be Filled?

The speed at which injection molds are filled is influenced by various factors including the type of injection molding machine, the viscosity of the plastic materials used, and the size and shape of the products being manufactured. Ordinary small machines ...

MANUFACTURING

How Does the Tonnage of an Injection Molding Machine Affect Injection Volume?

This article explores how the tonnage of an injection molding machine impacts injection volume. It discusses the relationship between clamping force, mold size, and injection pressure while emphasizing that higher tonnage allows for larger molds and better filling of complex ...

MANUFACTURING

How Does Mold Thickness Impact the Quality of Injection Molded Products?

The thickness of a mold plays a crucial role in the quality of injection molded products. It affects cooling speed, which in turn impacts dimensional accuracy; thicker molds cool more slowly, potentially leading to shrinkage and warping. Additionally, thicker molds ...

MANUFACTURING

How Does Standard Mold Thickness Affect Injection Molding Process Parameters?

The thickness of a mold plays a critical role in the injection molding process, impacting various parameters such as mold opening stroke, injection pressure, cooling time, and overall product quality. Thicker molds require careful adjustments to ensure smooth operation and ...

MANUFACTURING

What Are the Key Criteria for Mold Opening Stroke and Mold Thickness Range in Injection Molding Machines?

Selecting the right injection molding machine involves understanding mold opening stroke and thickness ranges. Small machines typically have strokes between 150mm to 650mm and thicknesses from 100mm to 400mm. Medium-sized machines range from 600mm to 1500mm in stroke and can ...

MANUFACTURING

How Does Tonnage Size Impact the Properties of Injection Molded Products?

The tonnage size of injection molding machines plays a vital role in determining the quality of molded products. High tonnage ensures strong clamping force, which is essential for maintaining dimensional accuracy by preventing mold expansion during the injection process. This ...

MANUFACTURING

What Factors Determine the Best Injection Molding Machine for Your Product Size and Weight?

Choosing the right injection molding machine is crucial for manufacturing success. Key factors include product size and weight, which influence clamping force calculations using projected area. Mold size must match machine capacity to ensure smooth production. Additionally, understanding injection volume ...

MANUFACTURING

How Do You Select the Right Tonnage for an Injection Molding Machine?

Choosing the correct tonnage for an injection molding machine is crucial for producing high-quality plastic products. Key factors include calculating the projected area of the product to determine necessary clamping force using the formula F = p × A, where ...

MANUFACTURING

How Do You Choose the Right Injection Molding Machine for Your Product’s Size and Weight?

Selecting the appropriate injection molding machine is crucial for manufacturing efficiency and product quality. Key factors include understanding the projected area for clamping force calculations, ensuring mold size compatibility with machine specifications, and determining injection volume based on product weight ...

MANUFACTURING

What Factors Determine Excessive Cooling Time in Injection Molds?

This article explores the critical factors affecting excessive cooling times in injection molds. It highlights how product thickness and material type influence cooling duration, which can lead to decreased production efficiency and compromised product quality. For instance, thin-walled parts should ...

MANUFACTURING

What Factors Should You Consider When Choosing a Mold Surface Treatment Process?

When selecting a mold surface treatment process, several factors must be considered to ensure optimal performance. Key considerations include the wear resistance needed for high-filler materials like glass fiber-reinforced plastics, corrosion resistance for molds used with corrosive plastics such as ...

MANUFACTURING