Have you ever wondered why injection moulds come with such a hefty price tag? Let’s dive into the fascinating world of mould manufacturing and uncover the reasons behind these costs!

The high cost of injection moulds arises from several factors: intricate design requirements, expensive materials like high-grade steel, advanced processing technologies, and extensive trial and debugging phases. Each aspect requires significant investment in skilled labor, technology, and time.

While the initial answer highlights some critical cost drivers, a deeper dive into each element reveals the nuanced challenges that manufacturers face. Understanding these intricacies can guide more informed decisions about using injection moulding in your projects.

Injection moulds are expensive due to high-quality material needs.True

High-quality materials like specialized steels enhance durability, increasing costs.

How Does Design Complexity Affect Injection Mould Costs?

Design complexity is a significant factor that influences the overall cost of injection moulds. But what makes these designs so costly?

Complex injection mould designs increase costs due to high professional fees, advanced software needs, and intricate processing requirements. Each layer of complexity demands more resources, time, and expertise, driving up the cost of manufacturing.

Professional Designer Fees

Injection mould design requires experienced professionals with a deep understanding of materials, mechanical engineering, and moulding processes. The expertise of these professionals comes at a premium. For instance, a seasoned designer’s annual salary can reach hundreds of thousands of yuan. Complex projects often necessitate the collaboration of multiple designers, which significantly raises the labour costs.

Investment in Advanced Design Software

Modern mould designs rely heavily on sophisticated CAD and CAE software. These tools are crucial for ensuring precision and quality in design but come with substantial costs. Not only are these software solutions expensive, but they also require regular updates and maintenance to stay effective. Furthermore, companies must invest in comprehensive training programs to maximize the benefits of these technologies.

| Software Type | Annual Maintenance Cost |

|---|---|

| CAD Software | Tens of thousands of yuan |

| CAE Software | Tens of thousands of yuan |

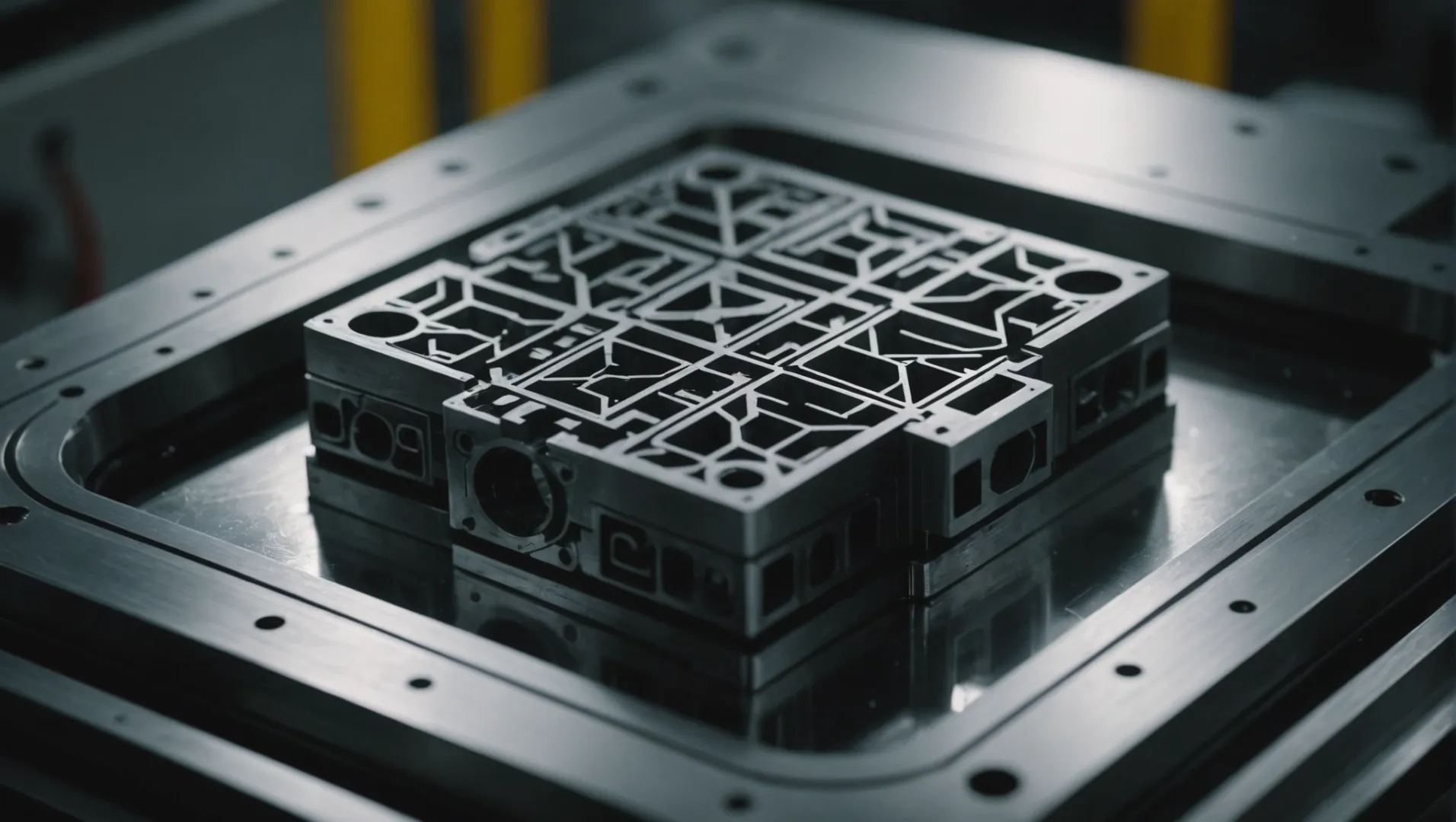

Intricate Processing Requirements

The complexity of a design dictates the level of detail required in the manufacturing process. This often involves the use of high-precision machinery like CNC machining centers and EDM machines. Such equipment is not only costly to purchase but also requires regular maintenance and skilled operators, adding further to the overall cost.

Multiple Processing Technologies and Extended Cycles

As designs become more intricate, they demand a variety of processing technologies—milling, drilling, tapping—to name a few. Each of these processes requires time and skilled manpower. Moreover, complex moulds can take weeks or even months to produce, with each phase contributing to the escalating costs.

Real-World Examples

Consider a scenario where a company invests in an advanced five-axis CNC machine costing millions of yuan. The operating expenses, including electricity and tool wear, further add to this cost. Additionally, the need for highly skilled operators increases labour expenses.

Understanding these aspects highlights why design complexity is a significant cost driver in injection mould manufacturing. It underscores the importance of balancing design ambitions with budgetary constraints to make informed manufacturing decisions.

Complex designs require advanced CAD software.True

Advanced CAD software is essential for precision in complex designs.

Simple mould designs demand multiple processing technologies.False

Simple designs typically require fewer processing technologies.

What Role Do Material Choices Play in Increasing Mould Expenses?

Choosing the right materials for mould manufacturing is crucial, impacting both cost and performance. Why does this choice significantly inflate expenses?

Material choices in mould manufacturing affect costs due to the need for high-quality, expensive materials like specialized steels and alloys. These materials enhance durability and performance but also require costly processing and treatments, contributing significantly to overall mould expenses.

Importance of High-Quality Materials

The selection of high-quality materials such as specialized steels and alloys is critical in injection mould manufacturing. These materials ensure the durability, strength, and precision required for producing high-quality plastic products. However, they come at a premium price. For instance, imported high-performance steels are often used for their superior properties, costing several times more than standard steel.

Impact of Material Processing and Treatments

Once the appropriate material is chosen, it must undergo various processing and heat treatments to enhance its performance. This includes processes such as quenching and tempering, which improve hardness and strength. However, these treatments require advanced equipment and skilled operators, leading to higher processing costs.

| Treatment Type | Purpose | Cost Factor |

|---|---|---|

| Quenching | Increases hardness | High energy consumption |

| Tempering | Improves strength | Skilled labor required |

| Surface Coating | Enhances wear resistance | Specialized equipment |

Diverse Material Requirements for Different Mould Parts

Different parts of a mould may require different types of materials based on their function. This diversity in material requirements can increase costs because each type may have unique sourcing, processing, and treatment needs. For example, the core of the mould might need a different alloy compared to the cavity to withstand higher stress levels.

The Cost of Advanced Alloys

High-performance alloys are often necessary to meet specific engineering demands in complex mould designs. These alloys are not only expensive but also hard to source, particularly if they are imported. Their cost is justified by their ability to endure extreme conditions, which is vital for maintaining the quality and longevity of the mould.

Understanding these aspects of material selection can help businesses make more informed decisions about choosing the right materials1 for their moulding projects.

High-quality materials increase mould expenses significantly.True

Specialized steels and alloys are costly but enhance mould durability.

Standard steel is often used in injection mould manufacturing.False

High-performance, imported steels are preferred for their superior properties.

Why Is Advanced Processing Technology Essential for Mould Manufacturing?

In mould manufacturing, precision is paramount. Advanced processing technology ensures unparalleled accuracy and efficiency in creating intricate mould designs.

Advanced processing technology is essential in mould manufacturing because it enables precision, efficiency, and high-quality output. The use of cutting-edge CNC machines, EDM, and other technologies reduces errors, speeds up production, and ensures that complex mould designs meet stringent quality standards.

Precision in Design and Execution

Mould manufacturing demands exceptional precision to ensure each component fits perfectly and functions as intended. Advanced technologies, such as CNC machining2 and EDM3, allow manufacturers to achieve this level of accuracy. CNC machines operate with computer-controlled precision, executing complex designs that manual processes cannot replicate. This precision is crucial for intricate parts where even minor errors can lead to significant performance issues.

Efficiency and Time Savings

Utilizing advanced processing technology not only enhances precision but also significantly improves production efficiency. High-speed CNC machines reduce the time required for machining each part. Moreover, technologies like EDM can cut through hard materials quickly without compromising on quality. These advancements help manufacturers meet tight deadlines while maintaining high standards.

Table: Key Technologies in Mould Manufacturing

| Technology | Functionality | Benefits |

|---|---|---|

| CNC Machining | Automated, precise shaping of materials | High precision, reduced labor costs |

| EDM | Shapes complex geometries and hard materials | Improved accuracy for hard-to-machine areas |

| Wire Cutting | Precise cutting of conductive materials | Fine detail work with minimal material wastage |

Quality Assurance

Advanced technologies play a crucial role in maintaining quality standards in mould manufacturing. Automated processes ensure consistency across production runs, reducing the risk of defects. Moreover, real-time monitoring systems can detect anomalies during production, allowing for immediate corrective actions to be taken.

Cost Implications

While the initial investment in advanced processing technology can be substantial, the long-term cost benefits are undeniable. Precision reduces material waste, efficiency shortens production cycles, and quality assurance minimizes costly rework and returns. As a result, manufacturers often find that these investments pay off through improved product quality and faster turnaround times.

Embracing these technologies not only enhances the capabilities of mould manufacturers but also aligns with industry trends towards automation and innovation. For businesses aiming to stay competitive in a rapidly evolving market, leveraging advanced processing technology is no longer optional—it’s essential for success.

Advanced tech reduces errors in mould manufacturing.True

Advanced technologies ensure precision, reducing errors significantly.

Manual processes are more precise than CNC machines.False

CNC machines offer computer-controlled precision surpassing manual methods.

How Do Trial and Debugging Processes Add to Overall Costs?

Trial and debugging in mold manufacturing are crucial yet costly steps. What are the hidden expenses?

Trial and debugging processes increase costs due to high raw material consumption, equipment usage, and significant manpower needs for multiple adjustments.

Raw Material and Equipment Usage

The trial phase of injection mold manufacturing involves using actual production materials, such as plastic pellets, which can add considerable costs. Each trial run consumes a substantial amount of these materials, often reaching dozens or even hundreds of kilograms. This not only raises material costs but also affects the overall budget significantly.

Moreover, equipment usage during trial runs can be costly. Injection molding machines, which are pivotal in this process, accrue substantial operational costs. The wear and tear on the machines also contribute to maintenance expenses over time.

For example, a single trial can result in raw material costs totaling thousands of yuan, alongside equipment usage expenses that further strain the budget.

Manpower and Time Investment

Trial and debugging require skilled technicians to conduct multiple rounds of adjustments and inspections to ensure molds produce quality products. This iterative process is labor-intensive, demanding experienced personnel who can identify and rectify issues swiftly.

Each adjustment requires a comprehensive analysis of mold performance, identification of defects, and implementation of corrective measures. This cycle can repeat numerous times, especially with complex molds, leading to significant time investments. The cumulative labor hours required during this phase add a hefty sum to the overall cost.

To illustrate, a complex mold might necessitate over a dozen debugging sessions, with each session involving various technicians working in concert to achieve the desired results.

Case Study: Cost Breakdown

| Cost Component | Estimated Cost (Yuan) |

|---|---|

| Raw Material (Plastic Pellets) | 5,000 |

| Equipment Usage (Per Trial) | 2,000 |

| Technician Labor (Per Adjustment) | 1,500 |

| Total for Multiple Debug Sessions | 25,000 |

The table above demonstrates a typical cost breakdown for trial and debugging processes in mold manufacturing. Each component contributes significantly to the overall expenses, highlighting the importance of optimizing these phases to control costs effectively.

Optimizing Trial and Debugging Phases

Reducing costs in the trial and debugging stages involves implementing efficient practices such as predictive simulations and leveraging advanced technologies like computer-aided design (CAD). These tools can help anticipate potential issues before physical trials begin, thus minimizing unnecessary iterations.

Furthermore, continuous training of technicians in advanced troubleshooting methods can enhance efficiency during debugging sessions. By investing in employee training4, companies can reduce the number of required adjustments, thus saving on labor costs.

Optimizing these processes not only reduces expenses but also accelerates time-to-market for new products, ultimately enhancing competitive advantage.

Trial runs use actual production materials.True

Trial runs consume significant raw materials, impacting costs.

Technician labor is minimal in debugging processes.False

Debugging requires skilled technicians for multiple adjustments.

Conclusion

Grasping the complexities behind injection mould costs empowers better decision-making in manufacturing. Balancing design, material choice, and processing strategies can help stakeholders optimize their approach and potentially reduce costs.

-

Explore factors influencing material selection for optimal mould performance.: Comparing Injection Molding Materials. Tough, stiff, hard, and strong. Good lubricity and resistance to hydrocarbons and organic solvents. ↩

-

Discover how CNC machining enhances precision and reduces costs.: The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency. ↩

-

Learn about EDM’s role in achieving intricate mould designs.: Often called a “Hole Popper,” the drilling EDM functions using a spinning electrode rod to “drill” into materials. In the most simple form, … ↩

-

Training boosts efficiency in mold debugging, reducing labor costs.: It is an investment in the safety, wellbeing, and personal development of your employees. When everyone is on the same page with consistent training, fewer … ↩