All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Are the Best Practices for Choosing Materials in Medical-Grade Injection Molding?

Selecting the right materials for medical-grade injection molding is crucial for developing safe and reliable medical devices. Key factors include sterilization compatibility, mechanical properties like tensile strength and elasticity, biocompatibility to prevent adverse reactions, and adherence to regulatory standards. Understanding ...

Materials Recommendations

What Are the Challenges of Injection Molding Large-Scale Parts?

This blog explores the complexities of injection molding large-scale parts, highlighting challenges such as managing material volumes, ensuring consistent quality, and dealing with extended cooling times. It emphasizes the importance of selecting appropriate materials to balance cost and performance while ...

MANUFACTURING

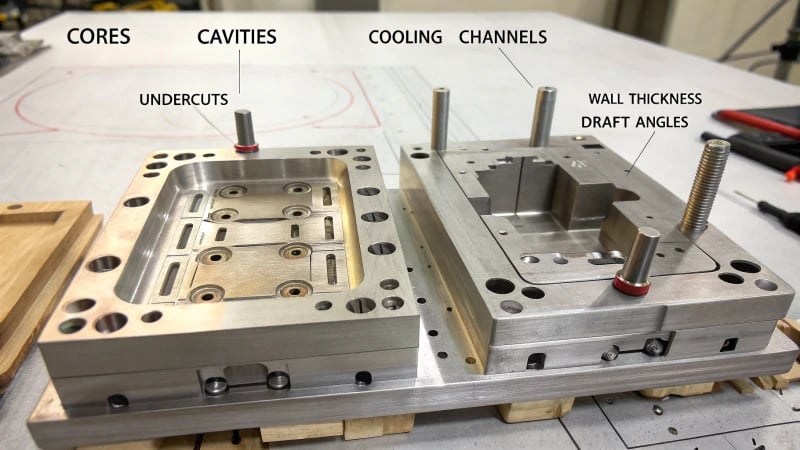

How Does Part Geometry Influence Mold Design in Injection Molding?

This article explores how part geometry affects mold design in injection molding. Key factors such as wall thickness, mold size, core shapes, and undercuts are discussed to highlight their influence on manufacturability and product quality. The importance of draft angles ...

MANUFACTURING

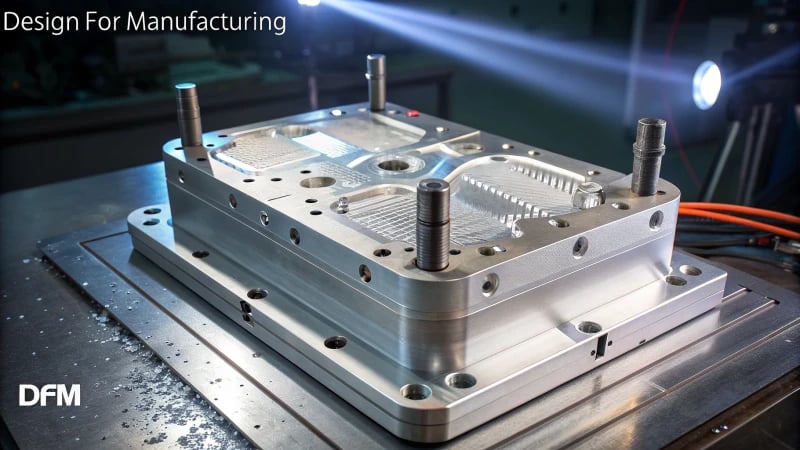

How Can DFM Principles Enhance Injection Mold Design?

Design for Manufacturing (DFM) principles significantly improve injection mold design by streamlining production processes, minimizing costs, and enhancing product quality. By focusing on simplicity, standardization, and ease of assembly, DFM helps designers create molds that are not only functional but ...

DESIGN

How Effectively Do Flame-Retardant Materials Perform in Injection Molding Applications?

This article explores the effectiveness of flame-retardant materials in injection molding applications, highlighting their crucial role in enhancing fire safety for consumer electronics. It discusses various types of flame-retardants, including halogenated compounds, phosphorous-based additives, and nitrogen-based synergists, each with unique ...

Materials Recommendations

How Does CAD Software Enhance the Design of Injection Molds?

CAD software significantly enhances the design of injection molds by improving precision and efficiency. Key features include 3D modeling for accurate visualization, simulation tools to predict performance, and automated documentation that streamlines communication. These capabilities not only reduce design time ...

DESIGN

What Are the Essential Factors in Designing Injection Molds for High-Volume Production?

Designing injection molds for high-volume production involves a blend of art and science. Essential factors include careful material selection, optimizing cooling systems, ensuring uniform wall thickness, and precise construction. Utilizing advanced technologies like CAD software streamlines the design process by ...

DESIGN

What Are the Latest Advancements in Thermoplastic Elastomers for Injection Molding?

Thermoplastic elastomers (TPEs) are transforming manufacturing with their unique blend of flexibility and durability. Recent advancements have led to enhanced material properties, new formulations, and innovative processing techniques that improve efficiency and reduce costs. TPEs allow for intricate designs, reduced ...

Materials Recommendations

How Does the Choice of Mold Base Impact Your Overall Mold Design?

The choice of mold base significantly influences overall mold design by affecting structural integrity, thermal performance, and production costs. Different types of bases—standard, custom, hot runner, and stripper plate—serve specific needs in manufacturing. Material selection also plays a vital role; ...

MANUFACTURING

What Challenges Arise When Molding Multi-Material Components?

Navigating multi-material molding involves overcoming challenges such as ensuring material compatibility, designing complex molds, and maintaining efficient production processes. This post explores common hurdles faced in the industry and offers practical strategies to enhance product quality and reduce defects. Key ...

MANUFACTURING

What Are the Key Benefits of ISO 9001 Certification for Injection Molding Operations?

ISO 9001 certification provides significant advantages for injection molding operations. It boosts efficiency, enhances product quality, and improves customer satisfaction. By standardizing processes and focusing on continuous improvement, companies can reduce waste and optimize resource management. This leads to consistent ...

Quality Inspection

How Can You Design Effective Molds for Thin-Wall Injection Molding?

Designing effective molds for thin-wall injection molding involves several key strategies. Focus on optimizing material flow and ensuring uniform wall thickness to prevent defects like warping or shrinkage. Precise temperature control is crucial for consistent results, while selecting appropriate materials ...

DESIGN

How Promising Are Multi-Material and Multi-Color Injection Molding Technologies?

This blog explores the transformative potential of multi-material and multi-color injection molding technologies in manufacturing. These innovations boost design creativity, streamline production processes, and enhance product functionality while reducing costs. However, they also pose challenges regarding recycling complexities and integration ...

OPTIMIZATION

How Does the Choice of Materials Impact the Recyclability of Injection-Molded Parts?

The choice of materials in injection molding is crucial for recyclability. Thermoplastics, such as Polypropylene (PP) and Polyethylene (PE), are more recyclable than thermosets due to their ability to be re-melted and reshaped. This article explores how selecting the right ...

Materials Recommendations

What Are the Essential Factors in Designing Multi-Cavity Molds?

Designing multi-cavity molds requires understanding essential factors such as material selection, cavity balance, cooling system design, and efficient ejection methods. These elements are crucial for achieving high production efficiency and consistent product quality. Material choices impact durability and cost-effectiveness while ...

DESIGN

How Does Automation Lower Labor Costs in Injection Molding?

Automation is revolutionizing the injection molding industry by significantly lowering labor costs. By taking over manual tasks, automated systems enhance production efficiency, ensure consistent quality, and minimize errors. This shift allows human resources to focus on strategic roles rather than ...

DEVELOPMENT

What Are the Best Practices for Core and Cavity Placement in Injection Molding?

In injection molding, effective core and cavity placement is crucial for minimizing defects and maximizing efficiency. Key practices include ensuring precise alignment, considering parting line locations, maintaining balanced wall thickness, and selecting appropriate materials. These strategies not only enhance product ...

MANUFACTURING

How Do Additives Impact the Properties of Injection-Molded Parts?

Additives play a crucial role in injection molding by modifying the properties of plastics to meet specific design requirements. They can enhance strength, flexibility, and durability through various types such as stabilizers, plasticizers, colorants, and reinforcements. Stabilizers protect against environmental ...

OPTIMIZATION

What Are the Cutting-Edge Trends in Injection Molding Technology?

The latest trends in injection molding technology focus on automation, sustainability, and novel materials. These advancements are revolutionizing the manufacturing industry by improving efficiency, minimizing environmental footprints, and creating new opportunities for designers. Automation enhances precision with robotics and sensors, ...

DEVELOPMENT

What Are the Most Effective Rapid Prototyping Techniques for Mold Making?

This blog post delves into the most effective rapid prototyping techniques for mold making. It covers 3D printing, CNC machining, and injection molding—each offering unique advantages in speed, precision, and cost-effectiveness. The article emphasizes how these methods can significantly enhance ...

MANUFACTURING

What Are the Key Factors to Consider When Designing Multi-Cavity Molds?

When designing multi-cavity molds, focus on optimizing cavity layout, balancing material flow, implementing effective cooling strategies, and minimizing defects. These key factors ensure efficiency and high-quality output in large-scale manufacturing processes. By mastering these elements, designers can significantly improve production ...

DESIGN

What Are the Key Differences Between Insert Molding and Overmolding?

This article explores the key differences between insert molding and overmolding in plastic manufacturing. Insert molding integrates pre-formed components into a mold, enhancing product strength and reducing assembly time. In contrast, overmolding adds layers of material to existing parts, improving ...

MANUFACTURING

What Are the Best Methods to Achieve Tight Tolerances in Injection Molding?

This blog post explores the best methods for achieving tight tolerances in injection molding. It emphasizes the importance of meticulous mold design, precise processing controls, and advanced simulation tools. Material selection plays a crucial role in influencing shrinkage rates and ...

DEVELOPMENT

What Are the Best Practices for Storing Injection Molds to Extend Their Life?

Proper storage and maintenance of injection molds are crucial for extending their lifespan. Key practices include storing molds in a dry, temperature-controlled environment, regular cleaning to prevent residue buildup, lubrication to reduce wear, and frequent inspections to catch potential issues ...

OPTIMIZATION

How Do Injection Molding and Die Casting Processes Compare and Combine?

This article explores the differences between injection molding and die casting, two essential manufacturing techniques for creating intricate components. While both involve injecting molten material into molds, they differ significantly in terms of materials used, suitability for specific applications, and ...

MANUFACTURING

What Are the Advantages of Using Recycled Materials in Injection Molding?

Integrating recycled materials into injection molding offers significant advantages such as cost savings, reduced environmental impact, and enhanced sustainability. While these materials can lower expenses and support eco-friendly practices, they also present challenges including quality inconsistency and contamination risks. Effective ...

DEVELOPMENT

How Do Plastic Ribs Enhance Injection-Molding Design?

Plastic ribs are crucial in injection-molding design, offering essential structural support while minimizing material use. They enhance part stability, reduce warping, and allow for thinner designs without compromising strength. By optimizing rib dimensions and placement, designers can improve product durability ...

DESIGN

How Is Wire Cutting Technology Revolutionizing Injection Mold Manufacturing?

Wire cutting technology, particularly Wire Electrical Discharge Machining (EDM), is transforming injection mold manufacturing. This advanced technique offers unparalleled precision for crafting intricate geometric shapes essential for modern molds. It streamlines post-quenching processes and ensures high-precision insert production, significantly enhancing ...

MANUFACTURING

How Is CNC Machining Revolutionizing Injection Mold Manufacturing?

CNC machining is transforming injection mold manufacturing through enhanced precision, reduced lead times, and increased efficiency. This technology allows for intricate designs that were previously challenging to achieve. By automating processes, CNC minimizes human error and waste while facilitating sustainable ...

MANUFACTURING

How Does Material Selection Affect Injection Molding Costs?

Choosing the right materials for injection molding is crucial as it affects costs, cycle times, and tool wear. Different materials like ABS, Polypropylene, Polystyrene, and Nylon offer unique properties suitable for various applications. Material selection influences mold design complexity, production ...

Price Evaluation