Did you ever think about how those perfectly shaped plastic pieces come to existence? Let’s discover the secrets behind producing very good injection molded parts!

To create high-quality injection molded parts, focus on selecting suitable raw materials, optimizing mold design, controlling the molding process, and carefully monitoring quality, ensuring both aesthetic and functional excellence.

During my time in injection molding, I realized crafting high-quality parts involves many important steps. Choosing the right raw materials matters a lot. Adjusting the mold design also holds great importance. Each step is crucial. We need to focus on every detail, similar to how a chef refines their dish. Even small mistakes can lead to bad results. In the next parts, I will share insights. I will give practical tips that improved my own production processes. These tips probably very much improved my product quality.

Raw material selection is critical for high-quality molds.True

Choosing the right raw materials directly impacts the quality and durability of injection molded parts, making it essential for production success.

Ongoing quality monitoring is unnecessary in injection molding.False

Continuous quality monitoring is vital to detect defects early and maintain high standards in injection molded parts, making it essential for production efficiency.

- 1. What raw materials are ideal for injection molding?

- 2. How does mold design impact product quality?

- 3. What parameters should I control during the injection molding process?

- 4. How can quality monitoring prevent defects in molded parts?

- 5. What are common pitfalls in injection mold design to avoid?

- 6. Conclusion

What raw materials are ideal for injection molding?

Selecting the right raw materials for injection molding resembles choosing the perfect ingredients for a special dish. These choices are important for achieving excellent results in your production process. Let’s explore the best options for your needs!

Ideal materials for injection molding include Polyamide (PA) for toughness, Polypropylene (PP) for lightweight applications, and Polymethyl methacrylate (PMMA) for transparency. Quality control and proper drying treatments enhance performance.

Understanding Raw Material Selection for Injection Molding

When I first started in injection molding, I quickly learned that the raw materials I chose had a huge impact on my projects. It’s amazing how something simple like plastic can greatly affect the final product. Picking the right material means knowing what your application needs and sometimes rethinking what’s really necessary.

The selection of raw materials is crucial for producing high-quality injection molded parts. Factors such as strength, toughness, heat resistance, and chemical resistance play significant roles in determining the ideal material. Here’s a detailed look:

- Commonly Used Plastics:

- Polyamide (PA): Great for tough parts. I used PA in a project requiring strong durability and it performed very well!

- Polypropylene (PP): This material is light and tough. It often helps me, especially in consumer goods where weight really matters.

- Polymethyl Methacrylate (PMMA): Offers clarity like no other. I once made a display case with PMMA and it was very clear.

Knowing your application’s needs is key. If you deal with parts facing high heat, it’s critical to select materials that tolerate high temperatures without issues.

Importance of Material Purity and Quality

I learned the importance of picking trustworthy suppliers early on. Good quality raw materials cut down defects. Trial and error taught me this valuable lesson. Key points for quality include:

| Indicator | Importance |

|---|---|

| Purity | Reduces defects in molded parts |

| Particle Size | Affects flow characteristics during molding |

| Consistency | Ensures uniformity in production |

Meeting these points differs between a perfect product and one with problems like bubbles or inconsistencies.

The Role of Drying Treatments

Many plastics, such as nylon (PA), soak up moisture from the air. I remind myself often about drying before injection molding:

- Drying Process: Dry these materials well to prevent defects.

- Temperature and Time: For instance, PA6 dries best at 80-100°C for 8-12 hours. This step is really worth the effort!

Color Matching and Additives

If color is important in your project, getting the color right is crucial. I usually:

- Add Masterbatch or Pigment: This helps spread color evenly, giving a consistent look.

- Use Additives: From flame retardants to antistatic agents, these additions can really increase performance based on needs.

These changes not only meet visual demands but also improve how the product works.

Summary of Ideal Raw Materials

Choosing raw materials for injection molding involves careful consideration of various factors including mechanical properties and environmental conditions:

| Material Type | Key Features | Typical Applications |

|---|---|---|

| Polyamide (PA) | High toughness, chemical resistance | Automotive parts, industrial components |

| Polypropylene (PP) | Lightweight, fatigue-resistant | Packaging, consumer products |

| Polymethyl Methacrylate (PMMA) | High transparency, UV resistance | Optical applications, displays |

For more details on improving material selection, check our guide on material properties in injection molding1.

Every project is unique. Take the time to explore your choices. It’s part of the adventure!

Polyamide (PA) is ideal for automotive parts due to toughness.True

Polyamide's high toughness makes it suitable for automotive applications, ensuring durability and performance under stress.

Polymethyl Methacrylate (PMMA) is not transparent.False

PMMA is known for its superior clarity and optical properties, making it ideal for applications requiring transparency.

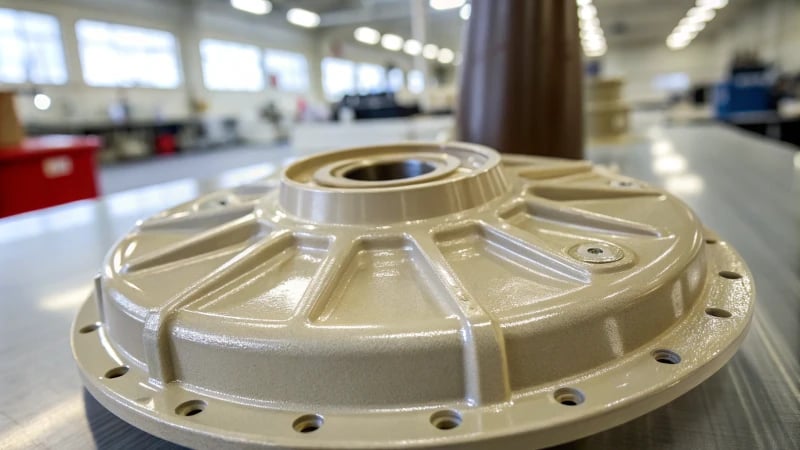

How does mold design impact product quality?

People often don’t realize how much mold design influences the products we use daily. Mold design plays a big part in creating these products. It is really interesting. This aspect is very important for people in manufacturing.

Mold design crucially influences product quality in injection molding by requiring suitable materials, precise manufacturing, and meticulous injection to produce strong, compliant products that satisfy customer and industry standards.

My time in this industry has shown me that even tiny decisions really matter!

For example, using the right raw materials can change how a product performs. In a project with car parts, we picked polyamide (PA) because it is very tough. This choice was critical. It helped our final product pass tough tests and met the high standards our clients expected.

Choosing materials is not just checking a box. It involves knowing what your product needs to succeed in the real world. Let’s look at some key details that shape mold design and affect product quality in injection molding!

The Importance of Mold Design in Injection Molding

As a new designer, I learned quickly that mold design isn’t just about creating a shape for plastic. It’s a craft that directly influences the quality of the final product.

Molded parts need several important factors: choosing raw materials, precise mold manufacturing and the injection molding process. Each part must be carefully controlled for the best results.

- Raw Material Selection and Processing

Selecting the right materials is like building a strong foundation for a house. If it’s not solid, everything can fail. One time, I chose polyamide (PA) for a project needing high durability. It was satisfying to see how it improved our product’s performance!

Remember the drying treatments are very important! Materials like nylon must be dried well to avoid problems during molding. I once skipped this step and ended up with bubbles in our final product. It was definitely a lesson learned!

Getting the color right and adding needed additives can improve performance a lot. Seeing a perfectly matched color in a product has been very rewarding – it’s great when looks and function come together!

- Mold Design Considerations

The actual mold design is where creativity and precision engineering meet.

Parting Surface Selection:

The location of the parting surface really affects the look and function of the final part. For products that need to look good, I always hide this surface cleverly. Small details like this make a big difference!

Gate Design:

The right gate type really influences how well plastic moves into the mold. For example:

Point Gates: Perfect for thin parts needing high aesthetics.

Side Gates: Suitable for regular-shaped parts.

Cooling System Design:

Even cooling stops warping – a lesson I learned from experience! Placing cooling channels carefully based on the part shape is critical. For round parts, I found circular cooling channels are great!

- Process Parameter Control

Controlling injection molding settings is like leading an orchestra – everything must work together!

During production, I often adjust parameters based on what I observe, which has improved product quality many times!

- Quality Monitoring and Optimization

Quality checks are my safety net during production. They help find defects early – something I really care about!

Appearance Inspection: Finding bubbles or flow marks early saves time and resources. I use both manual checks and automated systems to check thoroughly.

Dimensional Accuracy Detection: Precision tools are very useful here; they make sure parts are within specifications.

Performance Testing: Tests like checking tensile strength confirm that products meet industry standards.

Process Optimization: Making changes based on feedback from quality checks keeps production consistent and reliable.**

Grasping the Complex Relationship Between Mold Design and Product Quality in Injection Molding

Grasping the complex relationship between mold design and product quality in injection molding is crucial for success. Every person in this field should focus on this aspect. I have observed how focusing on every detail produces impressive outcomes. I want to share some insights that could be really helpful for you!

1. Raw Material Selection and Processing

Choosing the right raw materials can significantly affect the performance characteristics of the finished product.

For instance, selecting materials like polyamide (PA) or polypropylene (PP) for their toughness is essential for durable components.

| Material | Properties | Use Cases |

|---|---|---|

| Polyamide (PA) | High toughness, wear-resistant | Automotive parts, consumer goods |

| Polypropylene (PP) | Chemical resistance, flexible | Packaging, automotive components |

| PMMA | High transparency, optical clarity | Optical devices, displays |

Furthermore, proper drying treatment is vital for hygroscopic materials like nylon. This prevents defects during the molding process, ensuring quality outcomes. For example, drying PA6 at 80-100℃ for 8-12 hours is a common practice to achieve optimal moisture levels.

To enhance performance, additives such as flame retardants can be used, which should be evenly mixed to maintain consistency in properties. Accurate color matching is also crucial when aesthetics are a concern. Learn more about material selection2.

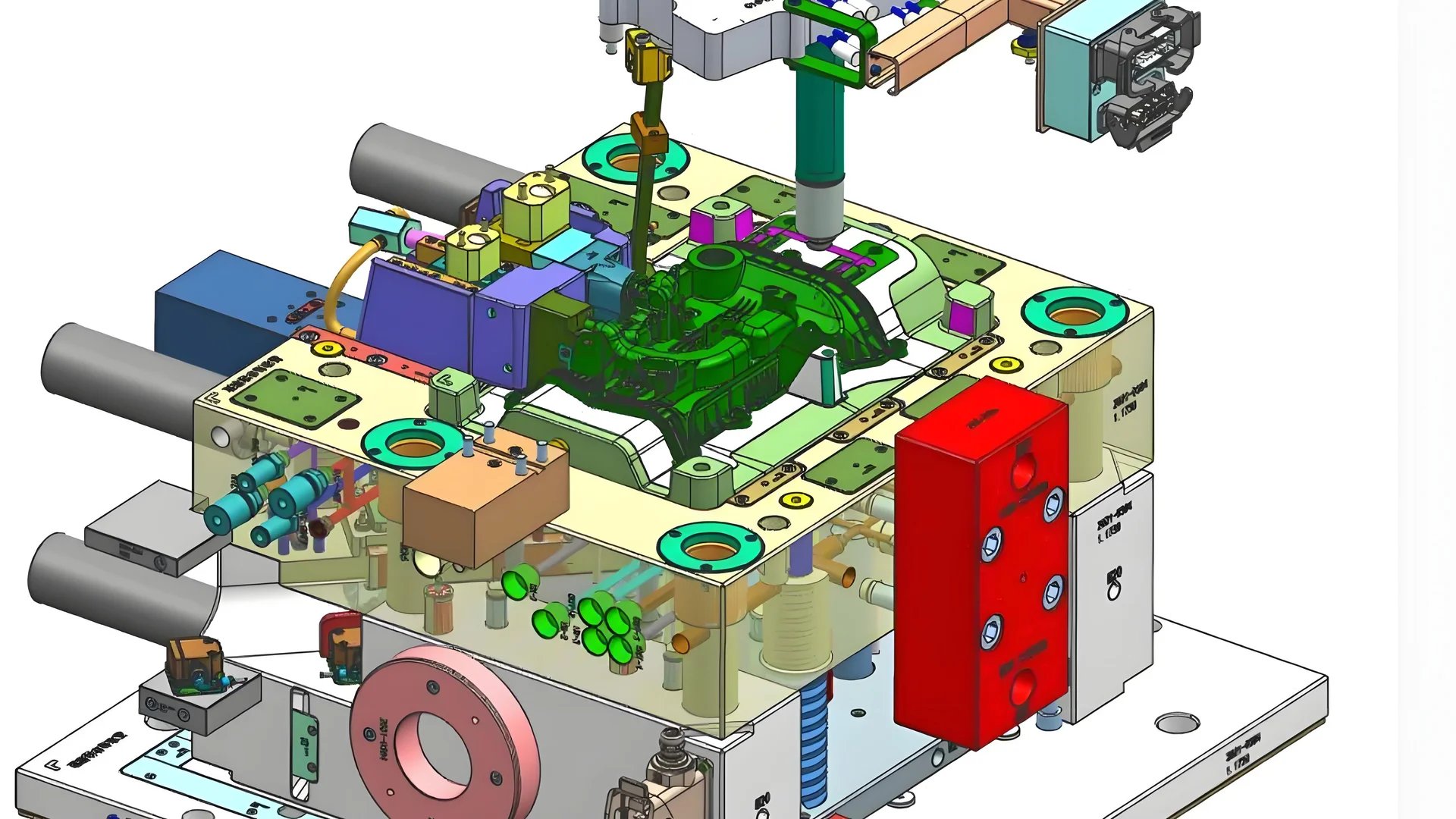

2. Mold Design Considerations

The design of the mold itself is equally important.

Parting Surface Selection:

The parting surface must be strategically placed to avoid affecting the part’s function and appearance.

For high-appearance products, this surface should be hidden effectively.

Gate Design:

Selecting the appropriate gate type affects flow rates and filling methods, crucial for producing high-quality parts. For instance:

- Point Gates: Best for thin-walled parts with high aesthetic requirements.

- Side Gates: Commonly used for regular-shaped parts.

Cooling System Design:

Even cooling distribution helps reduce warping. The layout of cooling channels should be optimized based on the part shape. For circular parts, a circular cooling channel is recommended. Explore advanced mold design techniques3.

3. Process Parameter Control

Effective control of injection molding parameters is essential for product quality.

| Parameter | Description | Impact on Quality |

|---|---|---|

| Barrel Temperature | Affects plastic fluidity; typically set at 180-220℃ | Ensures even melting and filling |

| Mold Temperature | Influences crystallinity and surface finish | Higher temperatures improve toughness and transparency |

| Injection Pressure | Must match fluidity and part requirements | Incorrect pressure can lead to defects |

| Holding Pressure | Compensates for shrinkage during cooling | Ensures uniform density and stable dimensions |

Adjustments to these parameters should be made based on real-time observations during production to optimize output quality. Find out more about parameter control4.

4. Quality Monitoring and Optimization

Quality assurance measures are crucial in identifying and addressing defects early in the production process.

- Appearance Inspection: Detects defects like bubbles or flow marks using both manual inspection and automated equipment.

- Dimensional Accuracy Detection: Employs precision measuring tools to ensure parts meet tolerance specifications.

- Performance Testing: Conducts tests such as tensile strength assessments to verify compliance with industry standards.

- Process Optimization: Adjusts parameters based on feedback from quality checks to enhance production consistency and reliability. Learn more about quality monitoring methods5.

Mold design directly influences product durability.True

Effective mold design ensures optimal material flow and cooling, which enhances the durability of injection-molded products.

Raw material selection has no impact on product quality.False

Choosing appropriate raw materials is crucial as it significantly affects the performance characteristics of the final product in injection molding.

What parameters should I control during the injection molding process?

Understanding injection molding might seem complicated. However, mastering key details turns it into an enjoyable experience. I will describe what I’ve discovered about important factors for producing high-quality items.

adjust injection and holding pressure, manage injection and mold operation speed, and conduct stringent quality checks and monitoring.

Temperature Control

I’ve explored injection molding and realized that temperature control is very important. Setting the right temperatures for the barrel and mold is crucial.

-

Barrel Temperature: I struggled with different plastics in my early days. Every plastic type needs a unique approach. For example, polystyrene usually needs a front section temperature between 180-220℃. Balanced temperatures lead to consistent plastic quality. This difference is noticeable.

-

Mold Temperature: Mold temperature isn’t just a number; it affects how the final product looks and feels. With crystalline plastics like polycarbonate, I learned raising the mold temperature (80-120℃) probably reduces internal stress. It really improves toughness and clarity.

Pressure Control

Changing pressure settings deeply affects product quality:

-

Injection Pressure: Understanding fluidity and part shape is very important. Insufficient pressure once caused incomplete filling, leaving us with useless parts. Too much pressure creates defects like flash. Balancing pressure is a challenge!

-

Holding Pressure: This is vital for managing shrinkage during cooling. I’ve adjusted holding times based on part thickness. Correct settings give uniform density and stable size.

Speed Control

Speed control is about precision:

-

Injection Speed: Finding the right injection speed changed everything for me. Too fast introduces air bubbles. Too slow leaves weld marks. Knowing your part’s needs, especially if thin-walled or intricate, is key.

-

Opening and Closing Mold Speed: Controlling mold speed really improves production efficiency. It also reduces wear and tear on the system.

Quality Monitoring and Optimization

Quality monitoring is essential, not just an extra step. Here are methods I’ve used:

| Inspection Type | Purpose | Tools/Methods Used |

|---|---|---|

| Appearance Inspection | Detect defects such as bubbles or flow marks | Manual checks and automated optical testing |

| Dimensional Accuracy Detection | Ensure dimensions meet design specifications | Calipers, micrometers, coordinate measuring machines |

| Performance Testing | Validate mechanical properties | Tensile strength tests, impact tests |

| Process Optimization | Adjust parameters based on monitoring results | Real-time data analysis |

Embracing these controls during injection molding optimizes output and minimizes errors. This results in high-quality molded parts for varied applications. If interested in specific parameter settings, check injection molding parameters6. Let’s continue learning!

Temperature control is essential for optimal plastic flow.True

Maintaining proper barrel and mold temperatures ensures the plastic melts correctly, influencing flow characteristics and overall product quality.

Higher injection pressure always leads to better molded parts.False

Excessive injection pressure can cause defects; thus, it must be balanced with part geometry and fluidity for optimal results.

How can quality monitoring prevent defects in molded parts?

Feeling frustrated with defects in molded parts happens often. I have been in that situation too. Quality monitoring is not just a technical need. It really changes everything. This approach probably improves product quality. It also keeps annoying errors away.

Quality monitoring in molded parts involves strict control over raw materials, regulation of process parameters, and thorough inspections during injection molding, preventing defects and enhancing product quality.

The Importance of Quality Monitoring

Quality monitoring is very important for the injection molding process as it directly impacts product integrity and performance. By implementing systematic quality checks at each production stage, manufacturers can significantly reduce defects. This approach gives me peace of mind, knowing I provide high-quality products.

Raw Material Inspection

Before production begins, quality monitoring starts with raw materials. The selection and testing of plastic materials are critical.

| Material Type | Properties | Testing Method |

|---|---|---|

| Polyamide (PA) | High toughness | Tensile strength test |

| Polymethyl Methacrylate (PMMA) | High transparency and optical properties | Visual inspection, light transmission test |

Choosing the right plastic materials is crucial. For high toughness, I choose polyamide (PA) or polypropylene (PP). It is not just about selecting a material; suppliers must be reputable and raw materials should meet all necessary specifications. I remember a project where choosing high-quality PMMA for its transparency made a major difference.

I dry hygroscopic plastics properly before production to avoid defects like bubbles. For instance, PA6 dries at 80-100°C for 8-12 hours. These little details are very important for avoiding future issues.

Process Parameter Control

Controlling process parameters like temperature and pressure during injection molding is essential for maintaining product quality. Each parameter must be carefully monitored and adjusted based on the material used:

- Temperature Settings: Influence plastic fluidity.

- Pressure Levels: Ensure molds fill completely without causing defects like flash or overflow.

Setting these correctly prevents many problems. Incorrect barrel temperature throws off flow characteristics. Adjusting these parameters suddenly is really important, especially during unexpected production issues.

For instance, setting the barrel temperature correctly for different plastics can improve flow characteristics:

| Plastic Type | Recommended Barrel Temperature (°C) |

|---|---|

| Polystyrene (PS) | 180-220 |

| Polycarbonate (PC) | 240-260 |

Regular Inspections

Regular inspections are very essential during the molding process. This includes:

- Appearance Inspections: Automated and manual inspections help catch surface defects early by detecting issues like bubbles or flow marks.

- Dimensional Accuracy Checks: Using precise measuring tools ensures that dimensions remain within tolerance levels.

| Inspection Type | Tools Used | Purpose |

|---|---|---|

| Appearance Inspection | Optical testing equipment | Detect surface defects |

| Dimensional Accuracy Check | Calipers, micrometers | Verify dimensional conformity |

By maintaining rigorous inspection routines, companies can catch defects early, preventing costly reworks later on.

Performance Testing

Performance tests such as tensile strength or impact resistance are crucial to confirm that my parts handle real-world applications effectively. Thorough testing builds confidence in my products.

To summarize, using strong quality monitoring practices at all stages—from selecting materials to post-production testing—helps prevent defects in molded parts efficiently. For more insights on optimizing quality monitoring systems, explore quality assurance techniques7 or industry best practices. Together, we probably can improve our manufacturing processes and deliver amazing results!

Quality monitoring reduces defects in molded parts.True

Systematic quality checks during production help identify and mitigate potential defects, leading to higher integrity and performance of molded parts.

Raw material inspection is unnecessary for defect prevention.False

Inspecting raw materials is crucial, as it ensures that only suitable materials are used, significantly reducing the risk of defects in the final product.

What are common pitfalls in injection mold design to avoid?

Designing injection molds often seems like a balancing act. Many things can go wrong. These issues often cause frustration and extra expenses. Let’s explore these challenges together. The goal is to make your process smoother and more successful.

Avoid common pitfalls in injection mold design by selecting the right materials, ensuring precise mold design, carefully controlling process parameters, and closely monitoring quality to produce high-quality parts efficiently.

Understanding the Importance of Raw Material Selection

One of the most critical pitfalls in injection mold design is the selection of raw materials. Choosing the wrong material can lead to parts that don’t meet performance requirements, resulting in high costs for rework or replacement.

For example, if a product requires high toughness, using materials like polyamide (PA) or polypropylene (PP) is advisable. On the other hand, if transparency is essential, polymethyl methacrylate (PMMA) should be considered. It’s crucial to verify the quality from reputable suppliers to ensure parameters such as purity and particle size are within acceptable limits. This detailed guide8 on raw material selection can provide deeper insights.

The Dangers of Inadequate Mold Design

Another common pitfall is poor mold design. If the mold’s geometry doesn’t align with the part’s requirements, this can lead to defects like warping or incomplete fills.

Key Considerations in Mold Design:

| Factor | Description |

|---|---|

| Parting Surface | Should be designed to minimize visibility and facilitate demolding. |

| Gate Design | Must consider the shape and size of parts for optimal flow. |

| Cooling System | Design cooling channels close to the cavity to ensure even cooling. |

For instance, selecting a point gate for thin-walled parts ensures that the melt fills evenly. If this is overlooked, defects may occur, leading to increased production costs.

Process Parameter Control Pitfalls

Failing to control process parameters like temperature and pressure can severely impact product quality. Each plastic type has specific requirements for these parameters, and deviations can lead to defects.

Temperature Control Table:

| Plastic Type | Recommended Barrel Temperature (°C) | Mold Temperature (°C) |

|---|---|---|

| Polystyrene (PS) | 180-220 | 20-60 |

| Polycarbonate (PC) | 230-260 | 80-120 |

It’s essential to maintain these temperatures throughout the injection process to avoid issues like internal stresses or poor surface finish. A good resource for temperature control best practices can be found here9.

Quality Monitoring and Its Importance

Lastly, neglecting quality monitoring can lead to unrecognized defects making it into production runs. Implementing a robust quality assurance process ensures that defects like bubbles or flash are identified early.

Quality Inspection Checklist:

- Appearance Inspection: Check for surface defects.

- Dimensional Accuracy Detection: Utilize calipers and coordinate measuring machines.

- Performance Testing: Verify tensile strength and heat resistance against standards.

Regular inspections based on this checklist can catch potential issues before they escalate into costly problems. For more on effective quality monitoring techniques, check out this comprehensive overview10.

Selecting the wrong raw material can lead to costly rework.True

Using inappropriate materials for injection molds can result in defects, increasing production costs due to rework or replacement of parts.

Poor mold design does not affect product quality.False

Inadequate mold design can cause defects like warping, directly impacting the quality and functionality of the final product.

Conclusion

This article outlines essential techniques for producing high-quality injection molded parts, focusing on raw materials, mold design, process control, and quality monitoring.

-

Learn about the best raw materials for injection molding to optimize your production process effectively. ↩

-

Discover how mold design intricacies influence product quality and performance in injection molding processes. ↩

-

Gain insights into advanced techniques in mold design that enhance manufacturing efficiency and product excellence. ↩

-

Learn about key parameters in the injection molding process that affect the final product’s characteristics and quality assurance. ↩

-

Explore best practices for monitoring quality in injection molding to improve defect detection and resolution. ↩

-

Explore detailed guidelines on optimizing injection molding parameters to enhance product quality and efficiency. ↩

-

Explore advanced techniques in quality monitoring to boost your product reliability and performance. ↩

-

Explore this link for valuable insights on avoiding design pitfalls that can lead to costly mistakes in injection molding. ↩

-

This link provides best practices for controlling process parameters in injection molding, essential for avoiding defects. ↩

-

Find effective quality monitoring techniques to ensure your molded parts meet high standards without defects. ↩