Navigating the manufacturing landscape can feel overwhelming, but what if I told you there’s a way to keep costs down without compromising too much on quality?

Cheap plastic injection molding reduces costs by using less expensive materials and simplified mold designs, making it ideal for products where high precision is not essential. This method supports cost-effective production with rapid prototyping capabilities, particularly beneficial for small batch runs.

But there’s so much more to explore! Understanding the full spectrum of benefits and limitations of this approach is crucial. Let’s dive into the details of how cheap plastic injection molding can fit your business needs.

Cheap injection molding is ideal for high-precision products.False

Cheap injection molding focuses on cost, not high precision, suitable for basic products.

What Are the Process Characteristics of Cheap Plastic Injection Molding?

Cheap plastic injection molding offers an economical way to produce plastics, focusing on cost-efficient processes and materials.

The key characteristics include the use of cost-effective materials, simplified mold designs, and a focus on applications where high precision isn’t critical. These features make it suitable for low-cost, high-volume production.

Cost Control Measures

Cheap plastic injection molding relies heavily on selecting cost-effective materials1 and streamlining mold designs. By choosing plastics that meet the basic functional requirements without the premium price tag, manufacturers can significantly cut down material costs. For example, opting for a basic polypropylene instead of a high-grade nylon can reduce expenses while maintaining adequate product functionality.

Moreover, simplified mold designs play a pivotal role in this cost-saving approach. Unlike molds with intricate core pulling mechanisms and advanced cooling systems, which are both costly and complex to produce, cheap injection molding utilizes basic structures. This simplification often means accepting certain trade-offs in precision and efficiency, but it drastically lowers initial tooling costs.

Scope of Application

This method is primarily utilized in scenarios where product appearance and precision are secondary concerns. It’s ideal for producing items such as disposable plastic utensils, low-end household goods, and industrial packaging components. These products typically do not demand high surface finishes or dimensional accuracies, making cheap injection molding a perfect fit.

Additionally, for rapid prototyping2 and small-batch production, this process shines by providing quick turnarounds at a fraction of the usual costs. In early-stage product development, being able to test and iterate designs without substantial financial risk is invaluable.

Balancing Advantages and Limitations

While the cost benefits are significant, it’s crucial to weigh these against potential quality compromises. For instance, products might display surface imperfections or lack the durability of those made with higher-quality processes. Similarly, because cheaper molds are used, they tend to have shorter lifespans, requiring more frequent replacements.

In summary, understanding these process characteristics3 enables businesses to strategically apply cheap plastic injection molding where it makes the most sense—balancing cost savings with product requirements.

Cheap injection molding uses cost-effective materials.True

It employs affordable plastics like polypropylene to reduce costs.

High precision is critical in cheap injection molding.False

Precision is often compromised to cut costs and simplify molds.

Where Is Cheap Plastic Injection Molding Most Effectively Used?

Cheap plastic injection molding is a cost-effective solution for various industries. But where is it most beneficial?

Cheap plastic injection molding is most effectively used in applications where product appearance and precision are secondary to cost, such as disposable items and low-end consumer goods. It excels in small batch production and prototyping, offering a balance between affordability and functionality.

Industries Benefiting from Cost Savings

In sectors where cost management is crucial, cheap plastic injection molding provides a viable alternative. For example, the packaging industry often prioritizes cost over high-end aesthetics. Products such as industrial packaging materials4 do not require intricate designs or superior finishes, making this method ideal.

Similarly, the food and beverage industry benefits significantly, particularly with disposable items like cutlery and containers. The lower material costs align perfectly with the need for economical, single-use products.

Low-End Consumer Goods

In the realm of low-end consumer goods, such as household items or basic office supplies, aesthetics and precision take a backseat to affordability. Cheap injection molding can meet the basic functional requirements for these items while keeping production costs down. Consider products like simple kitchen utensils5, where functionality trumps design intricacies.

Prototyping and Small Batch Production

Rapid prototyping is another area where this method shines. During the early stages of product development, companies need to test product feasibility without incurring hefty costs. Cheap plastic injection molding allows for the creation of prototypes at a fraction of the cost of traditional methods, facilitating quicker iterations and testing cycles.

Moreover, for businesses engaged in small batch production, this process offers a way to produce limited runs efficiently. It enables companies to test market responses with minimal financial risk before scaling up production.

Emerging Markets

In emerging markets, where consumers are highly price-sensitive, cheap plastic injection molding offers a means to produce affordable goods that meet basic needs. As these markets develop, the demand for low-cost products that deliver functionality over form continues to grow.

While cheap plastic injection molding does present some limitations regarding quality and durability, its strategic application in these specific areas showcases its potential to enhance production efficiency and cost-effectiveness.

Cheap injection molding suits disposable cutlery production.True

Disposable cutlery benefits from low-cost production, aligning with industry needs.

High-end consumer goods use cheap injection molding extensively.False

High-end goods require precision and aesthetics not provided by cheap molding.

What Advantages and Disadvantages Should You Consider?

Navigating the world of cheap plastic injection molding requires understanding its pros and cons. What should you weigh before diving in?

Cheap plastic injection molding offers cost savings and efficiency but may compromise on product quality and mold lifespan. Evaluating these factors is vital for effective application.

Advantages of Cheap Plastic Injection Molding

-

Low Cost: The primary advantage is the significant reduction in production costs. By utilizing less expensive raw materials and simplified molds, companies can produce more at a fraction of the price, especially beneficial for cost-sensitive products.

-

High Production Efficiency: Despite the lower costs, this method retains the high production efficiency inherent in injection molding, allowing for rapid mass production.

-

Capability for Complex Shapes: Cheap plastic injection molding can still cater to complex designs. It offers flexibility to create intricate shapes, which is advantageous for diverse product designs.

For instance, consider a company producing disposable cutlery or industrial packaging. These products do not demand high precision, making cheap injection molding an ideal choice.

Disadvantages to Weigh

-

Compromised Product Quality: Using cheaper materials and simpler processes can lead to products with visible defects, lower dimensional accuracy, and reduced mechanical properties. This may not be suitable for products requiring high durability or aesthetic quality.

-

Shorter Mold Life: To keep costs low, cheaper and simpler molds are used. While this reduces initial expenses, it may result in more frequent replacements due to a shorter lifespan.

Strategic Considerations

Before implementing cheap plastic injection molding, consider the following:

| Factor | Implication |

|---|---|

| Product Requirements | Assess whether the quality level aligns with the use of cheaper materials and processes. |

| Market Sensitivity | Analyze if your target market prioritizes cost over quality or vice versa. |

| Production Volume | Determine if the anticipated volume justifies the investment in mold creation versus other methods. |

For further insights, explore cost-effective injection molding strategies6 and see how businesses align their production needs with market demands.

Understanding these aspects ensures that you can leverage cheap plastic injection molding effectively, balancing cost savings with product requirements.

Cheap injection molding offers high production efficiency.True

Despite low costs, it allows rapid mass production, retaining efficiency.

Cheaper molds last longer than expensive ones.False

Cheaper molds have a shorter lifespan, leading to more replacements.

How Will Future Developments Impact Cheap Plastic Injection Molding?

The landscape of cheap plastic injection molding is set for transformation as new technologies and materials emerge.

Future developments in cheap plastic injection molding will enhance material quality, reduce environmental impact, and increase production efficiency. Innovations like biodegradable plastics and AI-driven mold design are expected to play pivotal roles in advancing this cost-effective manufacturing process.

Advancements in Material Science

One of the most significant future developments likely to impact cheap plastic injection molding is in material science. As environmental concerns grow, the push towards using more sustainable materials is gaining traction. Biodegradable plastics and recycled materials are becoming more available and affordable, making them viable options for cost-sensitive production.

For instance, new types of biodegradable plastics could offer similar cost benefits while improving environmental performance, addressing one of the critical drawbacks of traditional cheap plastics. These innovations could potentially revolutionize industries reliant on cheap plastic injection molding by minimizing their carbon footprint without compromising cost efficiency.

Technological Innovations in Molding Processes

Technological innovations are also set to redefine how cheap plastic injection molding is approached. The introduction of AI and machine learning in mold design can lead to significant improvements. AI-driven software can optimize mold design for enhanced precision while reducing waste and production costs. For example, using AI algorithms, manufacturers can simulate various scenarios to identify the most efficient mold designs, cutting down on trial-and-error and accelerating the prototyping phase.

Moreover, automation in the molding process can further increase production speed and consistency, leading to higher throughput rates without a corresponding increase in labor costs. This will particularly benefit companies engaging in small batch production or rapid prototyping.

Environmental and Regulatory Challenges

As the demand for environmentally friendly products increases, regulatory challenges will continue to evolve, impacting cheap plastic injection molding. Stricter regulations on emissions and waste disposal may necessitate changes in both material choices and production methods. Companies might need to invest in more advanced filtration systems or adopt closed-loop recycling processes to comply with these regulations.

In this context, staying informed about regulatory trends is crucial. Engaging with industry bodies and keeping abreast of changes can help businesses anticipate necessary adjustments and avoid potential penalties.

Market Dynamics and Consumer Expectations

Finally, market dynamics and changing consumer expectations will play a significant role in shaping the future of cheap plastic injection molding. As consumers become more eco-conscious, there is a growing expectation for products that are both affordable and sustainable. This shift could lead companies to prioritize investments in sustainable materials and more efficient production techniques.

Additionally, the increasing globalization of markets means that companies need to consider regional preferences and regulatory standards when designing products and choosing materials. For instance, what works in one market might not be suitable for another due to different environmental standards or consumer preferences.

By embracing these future developments, companies can enhance their competitiveness and meet both market demands and sustainability goals. Learn more about new materials in plastic molding7 or explore how AI is transforming manufacturing processes8.

Biodegradable plastics will replace traditional plastics.False

While biodegradable plastics are growing, they won't fully replace traditional plastics soon.

AI will reduce waste in injection molding processes.True

AI optimizes mold design, reducing waste and improving production efficiency.

Conclusion

By embracing cheap plastic injection molding, you can significantly cut costs while maintaining functionality, making it a smart choice for budget-conscious projects.

-

Explore different affordable plastics suitable for various injection molding applications.: Lowest cost materials for injection molding. Materials with the lowest cost, generally polypropylene and polyethylene, are incredibly versatile … ↩

-

Discover how rapid prototyping can save time and costs in product development.: 1. Accelerated Product Development · 2. Enables Testing of Design Functionality · 3. Enables Evaluation of Ergonomics · 4. Avoid Costly Mistakes Early On. ↩

-

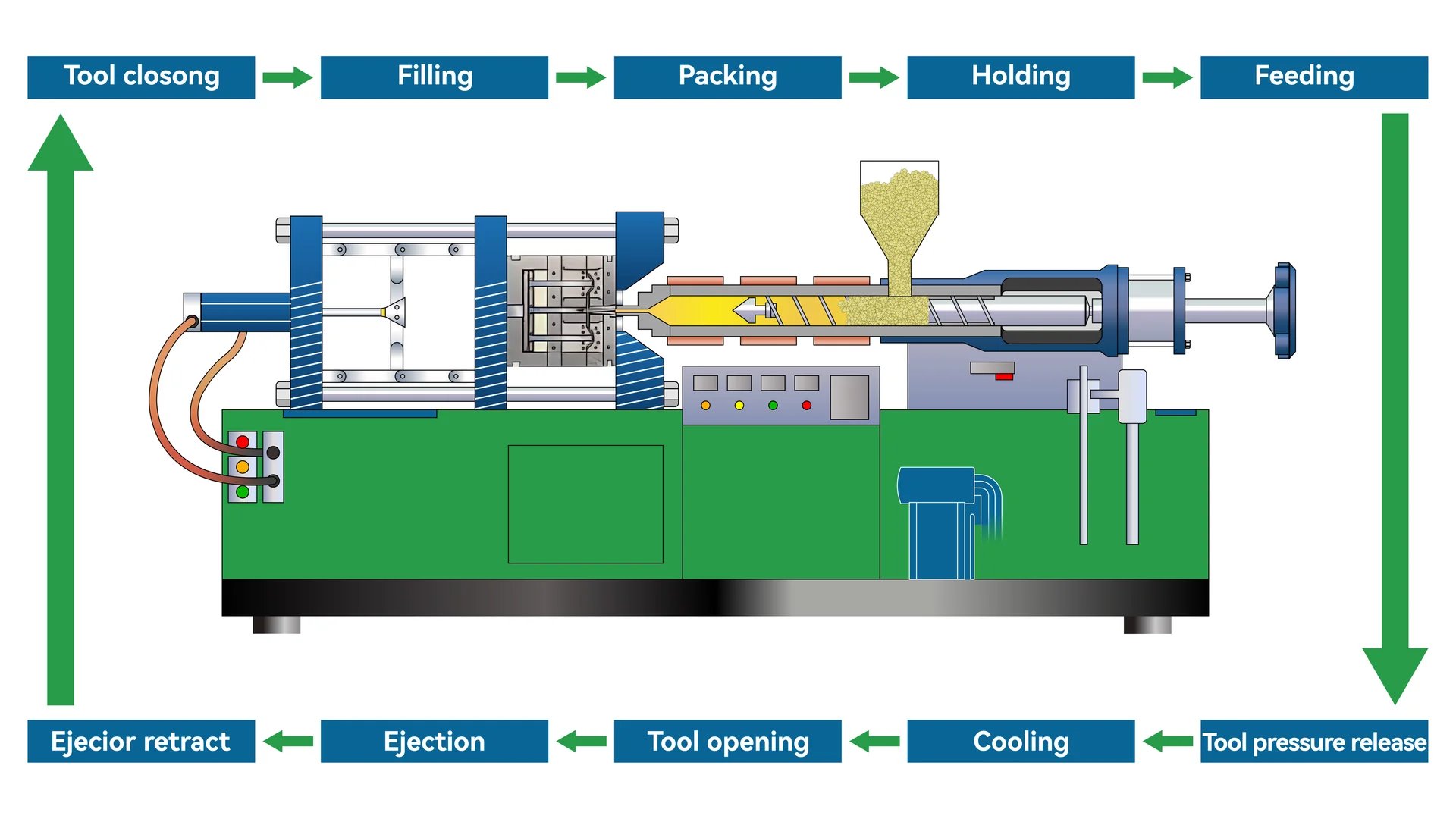

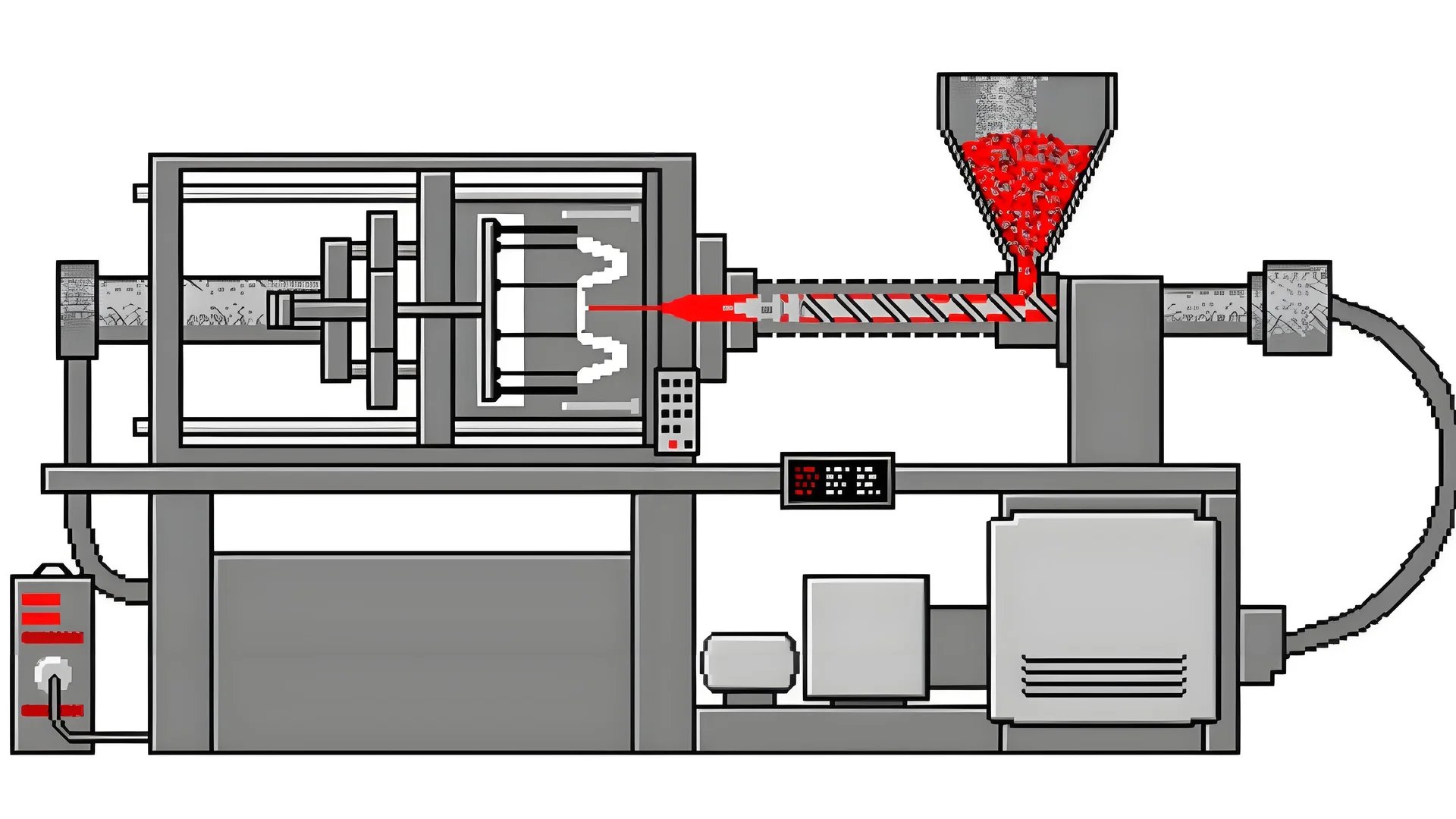

Learn about the key attributes that define different injection molding processes.: Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. ↩

-

Explore how this method reduces costs in packaging industry.: Plastic injection molding efficiently expedites packaging and processing applications in the foodservice industry. ↩

-

Discover how this technique suits low-end kitchenware.: What are the common things that are made with the help of injection molding? · Lids and Caps · DVDs and CDs · Entertainment Devices · Medical Apparatuses · Toys. ↩

-

Explore strategies to align production with market demands efficiently.: Explore key strategies for cost reduction in injection moulding, including design optimization, material selection, and efficient practices. ↩

-

Discover cutting-edge materials that enhance sustainability in plastic manufacturing.: Manufacturers recently began using plant-based materials in their injection molding to create plastics that are less harmful to the environment. ↩

-

Explore how AI optimizes efficiency and reduces costs in manufacturing.: AI is helping the manufacturing industry by improving efficiency, reducing costs, enhancing product quality, optimizing inventory management, and predicting … ↩