All Posts

blog & article

read our latest newsletter

Whether you’re curious about material selection, product design, mold design, mold making and injection molding, feel free to ask us anything. Our team is ready to provide the guidance and insights you need.

What Factors Determine the Best Injection Speed?

Choosing the right injection speed is crucial for optimizing plastic molding processes. Factors such as material characteristics (fluidity and heat sensitivity), mold design (gate size and runner system), and specific product requirements all influence the ideal injection speed. For instance, ...

MANUFACTURING

How Does Injection Pressure Impact the Quality of Injection Molds?

This article explores the critical role of injection pressure in molding processes, highlighting its impact on product quality, internal structure, and mold longevity. Properly adjusted pressure ensures complete filling of molds, enhances material properties, and extends the service life of ...

Quality Inspection

How is Injection Mold Injection Pressure Determined?

This article explores how injection mold pressure is determined by various factors including material characteristics, mold structure, and product requirements. Key aspects such as fluidity of plastics like polyethylene (PE) and polycarbonate (PC), gate size, runner system design, and the ...

MANUFACTURING

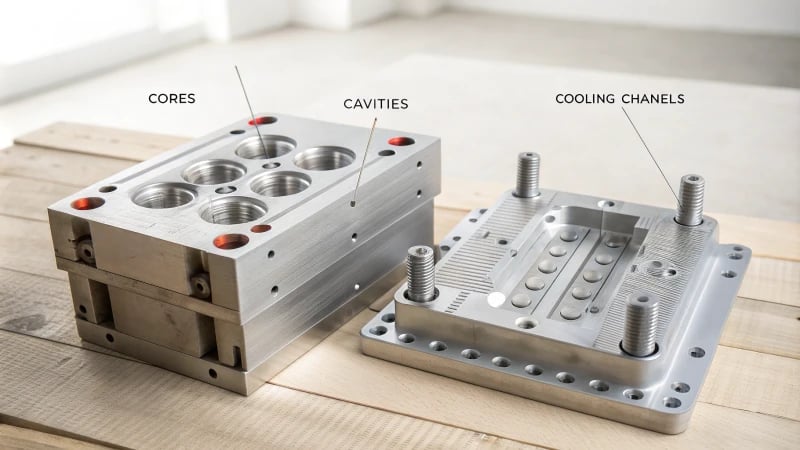

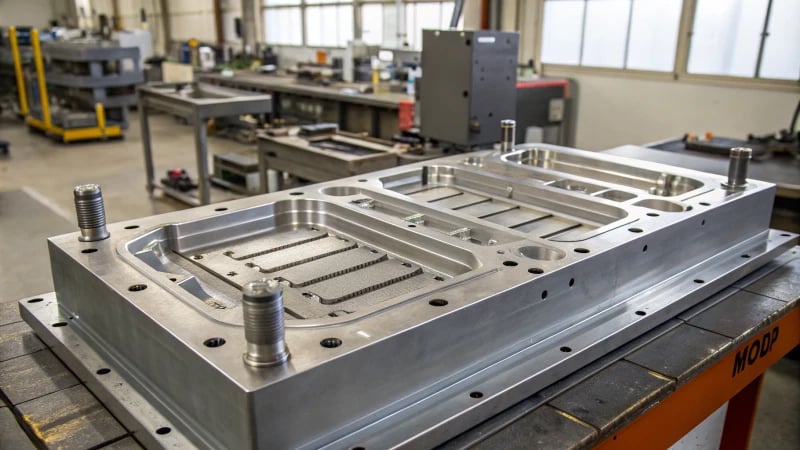

What Are the Functions of Each Part of an Injection Mold?

Injection molds consist of various critical components that work together to produce high-quality plastic parts. This article delves into the functions of each part: the casting system guides melted plastic; molded parts shape products; guide parts ensure precise alignment; ejection ...

DESIGN

What Key Details Should You Consider When Installing a Heating Ring?

Installing a heating ring on machinery demands precision and attention to detail. Key steps include inspecting the heating coil and barrel for damage, ensuring specifications match, achieving a snug fit for optimal heat transfer, securing electrical connections properly, and conducting ...

OPTIMIZATION

How Can Product Design Optimization Solve Warpage Defects in Injection Molded Parts?

This article explores how product design optimization can address warpage defects in injection molded parts. Key strategies include maintaining uniform wall thickness to ensure even cooling, strategically designing ribs to enhance strength without increasing thickness, and simplifying complex shapes to ...

OPTIMIZATION

How Do Warpage Defects Affect the Performance of Injection Molded Parts?

Warpage defects significantly impact the performance of injection molded parts by altering their dimensional accuracy, mechanical properties, and appearance. These issues arise from uneven cooling, material shrinkage, and poor mold design. Warped components can lead to assembly challenges and functional ...

OPTIMIZATION

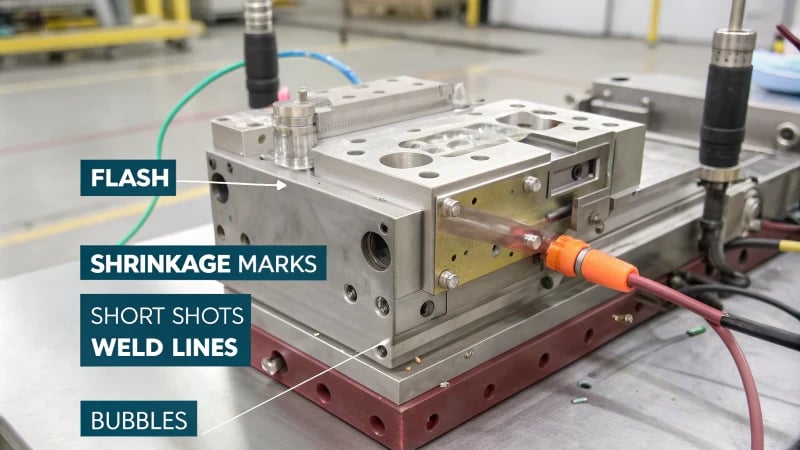

What Are the Most Common Defects in Injection Molding?

Injection molding can lead to various defects that affect product quality and efficiency. Common issues include flash caused by excessive pressure, shrinkage marks from uneven cooling, weld marks from flow convergence, bubbles due to moisture or poor venting, and short ...

Quality Inspection

How Can You Integrate Mold Design Standardization with Personalized Design?

This article explores how to effectively integrate mold design standardization with personalized elements. It emphasizes the importance of understanding product demand, developing a strategic design plan, and utilizing parametric design software to achieve a balance between creativity and efficiency. By ...

DESIGN

How Can You Effectively Minimize Shortcomings in Mold Design Standardization?

The article explores how to effectively minimize shortcomings in mold design standardization by encouraging innovation through incentive mechanisms, applying flexible standards, optimizing initial investment strategies, and enhancing adaptability to updates. It emphasizes the importance of collaboration among industry players to ...

DESIGN

How Does the Parting Line Affect the Precision of Injection Molded Products?

This article explores the critical role of parting lines in injection molding, emphasizing their influence on dimensional accuracy, shape integrity, and assembly position. Poorly managed parting lines can lead to issues such as flash formation, uneven surfaces, and misalignment in ...

MANUFACTURING

What Does the ‘Parting Line’ Mean in Injection Molding?

In injection molding, the parting line is where mold sections meet, significantly impacting both the aesthetic and structural qualities of the final product. Proper placement of this line is essential to avoid visible marks and stress points that can weaken ...

DESIGN

How Does Standardization Impact Injection Mold Design?

This article explores how standardization impacts injection mold design by establishing common rules for dimensions, specifications, and materials. It highlights the benefits of consistency in mold components such as templates, gates, runners, demolding mechanisms, and cooling systems. By following standardized ...

DESIGN

What Are the Key Advantages of Mold Design Standardization?

Mold design standardization streamlines the manufacturing process by using consistent parts and methods. This approach drastically shortens design cycles from weeks to days, boosts productivity, lowers production costs through bulk purchasing, and enhances product quality with reliable components. Standardized designs ...

DESIGN

How Do You Accurately Measure a Machine’s Heating Capacity?

Measuring a machine's heating capacity involves careful preparation and execution. Key steps include selecting appropriate tools like calorimeters and infrared thermometers, ensuring a safe environment, making precise connections, and documenting results meticulously. Proper calibration of instruments and attention to environmental ...

Quality Inspection

What Are the Key Steps to Becoming a Successful Mold Designer?

Becoming a successful mold designer requires a blend of theoretical knowledge, practical experience, and strong communication skills. Start by mastering the basics of mold design, including understanding different types of molds such as injection and stamping. Gain hands-on experience through ...

DEVELOPMENT

What Is the Service Life of an Injection Molding Machine’s Heating Coil?

The lifespan of heating coils in injection molding machines ranges from 5 to 10 years, depending on factors such as environmental conditions, operating temperatures, material quality, and maintenance routines. Ceramic coils generally outlast stainless steel ones. High humidity and corrosive ...

MANUFACTURING

How Do Injection Molding Machines Achieve Temperature Control in Their Heating Systems?

Temperature control is crucial in injection molding, acting as the heartbeat of quality production. This process relies on a combination of temperature sensors, controllers, and PID algorithms to maintain steady and precise heat levels. Sensors monitor real-time temperatures in various ...

MANUFACTURING

How Does Injection Molding Melt Raw Materials?

This article explores the intricate process of injection molding, focusing on how heating systems and shear heat work together to melt raw materials like plastics. The heating rings in the machine's barrel provide controlled temperatures that soften thermoplastics, while the ...

MANUFACTURING

What Are the Best Methods to Determine Gate Location and Size?

This article explores the best methods for determining gate location and size in injection molding. Proper gate placement is essential for achieving optimal melt flow balance, which directly impacts product quality by preventing defects such as air pockets and uneven ...

OPTIMIZATION

What Is the Best Gate Type for Optimizing Plastic Melt Fluidity?

Selecting the appropriate gate type in injection molding significantly influences the flow of molten plastic, impacting product quality and manufacturing efficiency. High viscosity plastics benefit from pin gates that increase shear heat, while low viscosity materials like polyethylene are better ...

OPTIMIZATION

What Are the Best Methods to Improve Plastic Melt Fluidity at the Gate?

This article explores effective methods to improve plastic melt fluidity during injection molding. Key strategies include optimizing gate design, controlling molding parameters such as temperature and pressure, selecting suitable high-fluidity materials like polyethylene and polypropylene, and incorporating additives such as ...

OPTIMIZATION

How Can You Choose the Right Processing Technology for Different Mold Material Characteristics?

Selecting appropriate processing technology for various mold materials is crucial for achieving optimal results. Factors such as material hardness, toughness, ductility, and thermal stability significantly influence tool selection and processing methods. High-hardness materials like H13 require carbide tools for effective ...

OPTIMIZATION

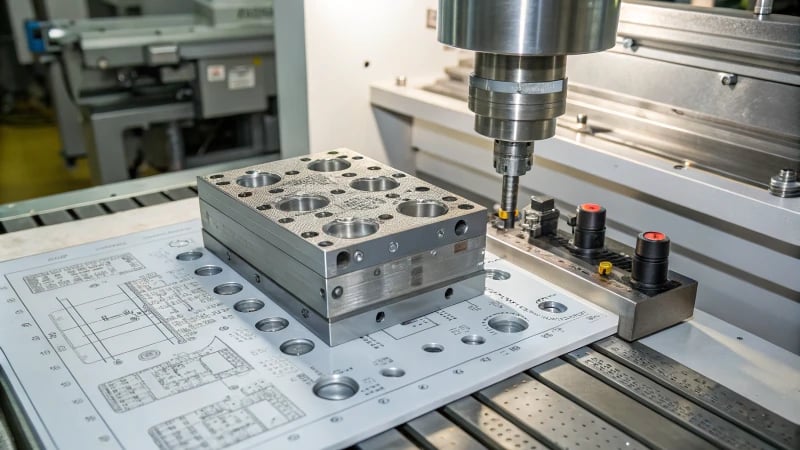

What Are the Key Factors Influencing Mold Processing Technology Choices?

Choosing the right mold processing technology is essential for manufacturing success. Factors such as design complexity, material characteristics, production requirements, available equipment, technician expertise, and budget constraints play a critical role in decision-making. Understanding how these elements interact helps manufacturers ...

MANUFACTURING

How Does Mold Processing Technology Affect Mold Service Life?

This article explores how mold processing technology affects the service life of molds. Key factors include dimensional accuracy, surface quality, and processing sequence. High precision in mold design ensures uniformity, reducing wear and preventing defects. Techniques like Electrodischarge Machining (EDM) ...

OPTIMIZATION

What Are the Key Principles for Choosing Mold Processing Technology?

Selecting the right mold processing technology is crucial for manufacturers. Key principles include prioritizing precision to meet strict standards, ensuring consistent quality across batches, balancing efficiency with cost-effectiveness, adapting processes to various materials and designs, and considering the operability of ...

MANUFACTURING

What Are the Key Factors to Consider When Choosing Mold Processing Technology?

Selecting the right mold processing technology is crucial for high-quality production. Key factors include design complexity, material characteristics, production quantity, equipment capabilities, technician expertise, and budget limits. Complex designs often require advanced techniques like high-speed milling or EDM for precision. ...

MANUFACTURING

What Are the Best Methods for Determining the Processing Technology of Complex Cavity Shape Molds?

Determining the best processing technology for complex cavity shape molds involves analyzing cavity characteristics such as surface type and internal structure. High-speed milling (HSM) is ideal for free-form surfaces, while Electrical Discharge Machining (EDM) excels in intricate designs. Material properties ...

MANUFACTURING

What Are the Key Considerations for Programming and Preparing Molds with Complex Cavity Shapes?

This article explores essential considerations for programming and preparing molds with complex cavity shapes. It emphasizes the importance of detailed shape analysis, effective tool path planning, appropriate cutting parameters, and selecting suitable CAD/CAM software. Additionally, it discusses the significance of ...

MANUFACTURING

What Is the Best Tool for Processing Molds with Complex Cavity Shapes?

Choosing the right tools for processing molds with complex cavity shapes is crucial for achieving precision and quality. This article discusses various milling cutters like ball-end, end, forming, and micro-diameter tools. It highlights the significance of selecting appropriate materials such ...

MANUFACTURING