Ever wonder how those complex plastic parts come to life? It’s all about precision and a bit of mechanical magic. Let’s dive into the heart of it all!

The core pulling mechanism in injection molds enables the production of complex internal features by retracting cores during or after mold opening, facilitating smooth product demolding without damage.

I remember the first time I watched an injection mold in action, I was fascinated by the seamless precision of the core pulling mechanism. This tiny component plays a colossal role in ensuring that even the trickiest parts are molded to perfection. It’s like watching a well-choreographed dance—everything moves in perfect sync to produce flawless results.

There are various types of core pulling mechanisms, each with its own perks and challenges. From the manual method, reminiscent of early days in mold factories, to the high-tech hydraulic systems that make you feel like you’re living in a sci-fi movie, each type serves a unique purpose. Understanding these mechanisms and their applications not only boosts efficiency but also enhances the quality of products. So, whether you’re a seasoned designer or just getting started, diving into these details can truly transform your approach to mold design.

Core pulling mechanisms create internal features in molded parts.True

Core pulling mechanisms retract cores to form internal features like holes.

Core pulling mechanisms are not essential for complex molds.False

They are crucial for creating intricate designs without damaging parts.

What Are the Key Functions of Core Pulling Mechanisms?

Ever wondered how those intricate plastic parts are made? It’s all about the core pulling mechanisms in injection molding. Dive in to discover their magic.

Core pulling mechanisms in injection molding enable lateral core removal, crucial for features like side holes or threads, ensuring product quality during mold opening.

The Role of Core Pulling Mechanisms

You know that satisfying click when you twist off a bottle cap? That’s part of the genius behind core pulling mechanisms. They’re critical in injection molding, especially for parts with lateral features like side holes or internal threads. These mechanisms ensure the core slides out smoothly when the mold opens, which prevents damage to those delicate features.

Examples of Application

- Plastic bottle caps: These often have intricate internal threads that require core pulling for seamless demolding.

- Electrical product casings: Side holes for buttons or connectors utilize core pulling to maintain precision.

It’s like watching a magic trick unfold, knowing there’s an art and science behind it.

Types of Core Pulling Mechanisms

Understanding the types of core pulling mechanisms is like having a toolkit for every occasion. Each type has its niche, and choosing the right one is crucial for success.

| Type | Features | Example |

|---|---|---|

| Manual | Simple, low-cost, suited for small batches | Small plastic molds |

| Motorized | High efficiency, includes inclined guide pins and bent pins | Plastic toys1, large containers |

| Hydraulic/Pneumatic | Large force and distance, costly setup | Automotive bumpers2 |

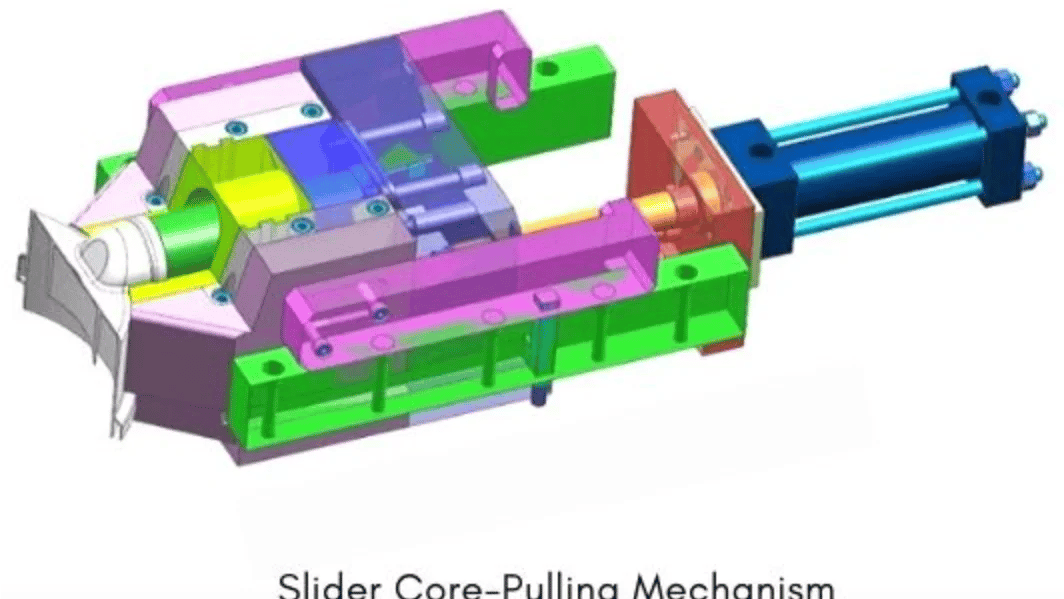

Motorized Core Pulling Mechanism

In my experience, the motorized type, especially with inclined guide pins, is a game-changer in high-volume productions. It’s like having a reliable co-pilot in your production line, ensuring precision and efficiency for products like plastic toys with complex side details.

Design Considerations

Designing core pulling mechanisms feels like crafting a masterpiece. Each element—from calculating the core pulling distance to ensuring slider and guide groove precision—requires attention to detail. Imagine you’re building a puzzle; every piece must fit perfectly for the whole picture to come together.

- Core Pulling Distance: This needs precise calculation to ensure nothing hinders demolding. Think of it as allowing just enough room for everything to move without a hitch.

- Core Pulling Force: Factors like plastic shrinkage and core shape influence this. It’s calculated using F = c×p × A, where F is force, c is clamping coefficient, p is clamping force per unit area, and A is area.

Slider and Guide Groove Design

The design of sliders and guide grooves is a testament to engineering finesse. Sliders need strength and durability while guide grooves ensure smooth movement—like butter on toast. A well-crafted wedge block3 keeps everything aligned under pressure.

Advanced Mechanisms

When complexity ramps up, hydraulic and pneumatic systems step in, offering flexibility and power for intricate designs needing significant core pulling force. Though they come at a cost, their ability to handle long distances and adaptable actions is invaluable in automotive mold design. It’s like upgrading from a sedan to a luxury SUV—more power, more capability.

Core pulling mechanisms prevent mold damage.True

They ensure smooth withdrawal of cores, protecting delicate structures.

Manual core pulling is ideal for high-volume production.False

Manual systems are suited for small batches due to simplicity and cost.

How Do Different Types of Core Pulling Mechanisms Compare?

Ever wondered how core pulling mechanisms in injection molding can make or break the design process?

Manual core pulling is cost-effective for small production, motorized systems enhance efficiency for larger scales, and hydraulic mechanisms offer strong force for complex molds.

Manual vs. Motorized Core Pulling

Manual Core Pulling Mechanism:

- Features: Simple structure, low cost, but labor-intensive.

- Application: Used in small-scale or trial productions. Imagine manually rotating a screw to extract the core in tiny molds; it’s hands-on and quite satisfying.

Motorized Core Pulling Mechanism:

- Features: High automation, utilizes mechanical transmission.

- Inclined Guide Pin Mechanism: Most common; integrates an inclined guide pin to pull the core during mold opening. Suitable for molds with side buckles like plastic toys4.

| Feature | Manual | Motorized |

|---|---|---|

| Cost | Low | Moderate |

| Efficiency | Low | High |

| Automation | None | Full |

When I first dipped my toes into the world of injection molding, manual core pulling was my go-to. It was like learning to ride a bike with training wheels—simple and reassuringly low-cost. On the flip side, when production scales up, motorized core pulling feels like switching from a bicycle to a scooter—speedy and efficient.

Exploring Advanced Options

Venturing into the more advanced realm, hydraulic or pneumatic systems are akin to driving a high-performance sports car. They provide immense force and versatility, ideal for those complex projects where manual methods just won’t cut it. I remember working on automobile bumpers with intricate side cores; the hydraulic systems handled them effortlessly.

This mechanism requires specialized devices, increasing cost but offering flexibility and power. Despite their higher cost, these mechanisms are indispensable in scenarios demanding significant force and flexibility. It’s like having a reliable powerhouse in your toolkit—essential for the heavy lifting in automotive plastic parts5 manufacturing.

Evaluating Design Considerations

Designing these mechanisms requires precision—it’s an intricate dance of calculating distances and forces. The core pulling distance must be exact, accounting for side hole depths plus a safety margin. I learned this lesson the hard way when an oversight led to a costly delay.

Additionally, crafting stable sliders and guide grooves is vital for accuracy. A well-designed wedge block can prevent any displacement under plastic melt pressure, much like a sturdy anchor in turbulent seas. Ensuring the wedge angle slightly exceeds the guide column’s inclination guarantees smooth mold closure—a small detail with a big impact.

For designers like Jacky, understanding these nuances ensures that core pulling mechanisms6 not only meet production demands but also uphold the integrity of every product we create.

Manual core pulling is labor-intensive but low-cost.True

Manual mechanisms require human effort, keeping costs low but increasing labor.

Hydraulic core pulling is unsuitable for complex molds.False

Hydraulic systems are ideal for complex molds due to their power and flexibility.

What are the key design considerations for effective core pulling?

Have you ever wondered how injection molds achieve such intricate designs without damaging the parts? It’s all about core pulling.

Key design considerations for effective core pulling include calculating force and distance, and designing sliders, guide grooves, and wedge blocks to ensure smooth demolding in injection molding.

Understanding Core Pulling Mechanisms

Core pulling mechanisms play a vital role during the injection molding7 process. They’re essential when dealing with structures like side holes or convex shapes. By moving cores laterally, these mechanisms prevent damage during demolding.

When I first dived into the world of injection molding, the concept of core pulling felt like unlocking a secret door to endless possibilities. Imagine you’re crafting something as detailed as a plastic bottle cap with internal threads—without damaging it during demolding. That’s where core pulling becomes your best friend. The mechanism allows these complex structures to be formed and removed without a hitch. It was like discovering the magic behind the scenes when I first saw it in action, and I immediately understood its importance.

Application Scenarios: Consider plastic bottle caps with internal threads. The core forming these threads must be withdrawn smoothly. Similarly, plastic shells8 with side holes require precise core pulling for features like button installations.

Types of Core Pulling Mechanisms

Manual Core Pulling Mechanism

- Features: As a designer, I’ve occasionally relied on manual mechanisms for smaller projects or trial productions. They’re straightforward and cost-effective, though admittedly labor-intensive.

- Example: Picture this: I’m working on a simple plastic mold, perhaps the kind that involves manually unscrewing cores. It’s an exercise in patience but can be quite satisfying.

Motorized Core Pulling Mechanisms

- Inclined Guide Pin: This is my go-to for efficient production. The synergy between the pin, slider, and side core is like watching a well-rehearsed dance.

- Commonly used in toy molds with side buckles.

- Bent Pin: Once, while designing a large container with side handles, I appreciated the increased pulling force and distance this mechanism provided.

- Allows greater pulling force and distance; often seen in large plastic containers with side handles.

- Inclined Slider: The integration here is fantastic. I remember using this in a project involving small plastic toys—it made simultaneous ejection and core pulling seamless.

- Integrates side core and slider for simultaneous ejection and core pulling.

Hydraulic and Pneumatic Systems

- Features: These systems are like the luxury cars of core pulling—powerful but pricey. I’ve seen them used in complex automotive parts, like bumpers, where their capabilities truly shine.

- Offer large pulling forces and long distances but are expensive; often used in automotive parts9 due to their complexity.

Key Design Points

Every time I tackle a new project, these design considerations are at the forefront of my mind. They’re not just technical guidelines; they’re keys to unlocking high-quality products that withstand the challenges of production. It’s a blend of art and science, ensuring each piece is crafted to perfection while maintaining efficiency and reliability.

| Design Aspect | Consideration |

|---|---|

| Core Pulling Distance | Must ensure no hindrance during demolding; typically a few mm beyond feature depth. |

| Core Pulling Force | Depends on plastic’s shrinkage rate and part’s geometry; calculated using $F = c \times p \times A$. |

| Slider Design | Requires strength and wear resistance; must reset accurately when mold closes. |

| Guide Groove Design | Should match slider size/shape for smooth operation; length at least 2/3 of slider’s length. |

| Wedge Block Function | Prevents displacement under plastic melt pressure; angle slightly larger than guide pin’s angle. |

Understanding these factors and implementing them effectively ensures the reliability and efficiency of core pulling mechanisms, which are vital to producing high-quality molded products without defects or damage during demolding10.

Manual core pulling is ideal for large-scale production.False

Manual core pulling is labor-intensive and suited for small batches.

Hydraulic systems offer large pulling forces and long distances.True

Hydraulic systems are powerful but expensive, ideal for complex parts.

How Does Core Pulling Influence Mold Efficiency and Product Quality?

Ever wondered how those complex plastic designs are made without a hitch? Core pulling is the secret sauce that makes it all possible!

Core pulling in injection molding enhances efficiency and product quality by allowing complex shapes, ensuring precise dimensions, and reducing defects.

The Role of Core Pulling in Mold Efficiency

Let me take you back to the time I marveled at how intricate designs, like the little side holes on a toy car or the threads inside a bottle cap, were molded. It was all thanks to core pulling mechanisms that smoothly retract lateral cores during or after mold opening. This process11 prevents damage and increases mold efficiency, just like when I watched a bottle cap’s internal threads form flawlessly because of this clever mechanism.

Imagine working on a project where every bottle cap comes out perfect, without any need for manual tweaks. That’s exactly what core pulling does—it ensures the mold operates seamlessly, saving precious time and boosting production speed.

Impact on Product Quality

Quality is everything when you’re creating precision parts. I remember the first time I held a plastic shell with side holes meant for buttons. Without core pulling, those holes could easily deform, affecting the entire product’s functionality. Core pulling mechanisms are like unsung heroes, preventing such errors and ensuring consistent quality across all production batches. It’s like having a reliable friend who always has your back.

Types of Core Pulling Mechanisms

- Manual Core Pulling: Picture yourself handcrafting each piece. It’s low-cost but labor-intensive, best for small runs or trial productions. Think of it like a cozy artisanal bakery compared to a bustling automated factory.

- Motorized Core Pulling: This is where things get exciting! Using inclined guide pin systems, it automates the process—less labor, more speed. It’s like upgrading from a typewriter to a laptop.

- Hydraulic/Pneumatic Systems: These are the big leagues, offering power and flexibility for complex molds like those in automotive parts. They’re costly but worth every penny when dealing with intricate designs.

Below is a table comparing these types:

| Type | Advantages | Disadvantages |

|---|---|---|

| Manual | Simple, low cost | Labor-intensive, slow |

| Motorized | Efficient, automated | Initial setup cost |

| Hydraulic/Pneumatic | Powerful, flexible | Expensive equipment needed |

Key Design Considerations

When I design a core pulling mechanism, it’s like putting together a puzzle. You’ve got to get the core pulling distance12 just right—usually the depth of side features plus a little extra (2-3mm for safety). The core pulling force? That’s all about understanding the materials and design specifics, like calculating how much strength you need without overdoing it.

The Importance of Material Selection

Choosing the right materials for components like sliders and wedges feels like selecting the perfect ingredients for a recipe. They need to handle wear and resist displacement under molten plastic pressure.

To dive deeper into core pulling mechanisms and how they can refine your production processes, check out this resource13.

Core pulling prevents product damage during demolding.True

Core pulling allows for smooth removal of intricate designs, avoiding damage.

Manual core pulling is ideal for large-scale production.False

Manual core pulling is labor-intensive and slow, unsuitable for large-scale production.

Conclusion

Core pulling mechanisms in injection molds are crucial for creating complex internal features, ensuring smooth demolding and product quality through various types like manual, motorized, and hydraulic systems.

-

Explore how motorized mechanisms improve efficiency in producing toys with intricate designs. ↩

-

Discover how hydraulic systems address complex requirements in automotive mold designs. ↩

-

Learn why wedge blocks are critical in preventing slider movement during molding. ↩

-

Explore how inclined guide pin mechanisms are applied in plastic toy molds, offering insights into their efficiency in large-scale production. ↩

-

Learn why hydraulic core pulling is crucial for automotive parts, providing the necessary force and flexibility for complex mold designs. ↩

-

Discover key design elements crucial for developing efficient core pulling mechanisms, ensuring reliability and product quality. ↩

-

Learn about the injection molding process to understand how core pulling fits within this manufacturing method. ↩

-

Explore examples of products requiring precise core pulling for features like button installations. ↩

-

Discover how complex automotive parts utilize hydraulic systems for effective core pulling. ↩

-

Understand demolding to see how core pulling aids in maintaining product integrity during removal. ↩

-

This link provides detailed insights into how core pulling functions within injection molding processes. ↩

-

Understand how to accurately calculate core pulling distances to optimize mold design. ↩

-

Discover cutting-edge techniques and innovations in core pulling for improved manufacturing. ↩