Welcome to another deep dive. This time, we're going to be getting pretty hands on with something that's essential to making countless everyday products, those made with injection molding. Have you ever wondered how a simple plastic toy or a complex piece of machinery actually gets its shape?

Yeah, I've always wondered.

It all starts with, well, molten material and a very carefully crafted mold, and getting that freshly molded product out of the mold smoothly. That's where these things called lifter release angles come into play.

It's a little bit like a magic trick, isn't it?

It is.

You have this liquid plastic takes on a precise form, and then, poof, it's released.

Right.

Seemingly effortlessly. But behind that poof is, well, there's a world of engineering and precision. And those release angles, they're really a critical part of that whole equation.

Okay, I'm intrigued. But before we get too deep into the technical stuff, can you give us, like, a quick overview of what exactly a lifter release angle is?

Absolutely. Imagine the mold as a set of these carefully shaped cavities. To get the product out, we need moving parts within the mold. And one of the most important is the lifter. Think of it as a small platform that rises up to push the molded product free.

Okay.

Now, the lifter release angle is the angle at which that lifter moves upwards. Sounds simple enough, right?

It does, but I have a feeling it's way more complicated than it sounds.

You're absolutely right.

Okay.

You see, if that angle is too shallow, the product might stick to the mold, and we really don't want that damaging both the product and the mold itself.

Yeah, that's not ideal.

We're talking potential production delays, costly repairs, a whole lot of scrap material. Not a good scenario.

So there's, like, a real financial incentive to get these angles just right.

Oh, big time.

Yeah, I guess, like, a fraction of a degree can make a huge difference.

Precisely. And that's where things start to get really interesting, because it's not just about the angle itself. The material we're molding, the shape of the. The product, even the size of the lifter, all these things come into play.

I'm starting to see how those seemingly minor details can have major consequences. Oh, yeah, speaking of materials, I noticed in the research that you sent over that, you know, some plastics are just notoriously tricky to work with.

Great.

Polypropylene was one example that stood out.

Ah, yes, Polypropylene, or PP, as it's commonly known. It's everywhere from food containers to car parts. But it has this one Little quirk that makes it a bit of a challenge in the molding process.

Okay, fill us in. What makes PP so special?

Well, PP has a high shrinkage rate. It can shrink by as much as 2 1/2% as it cools. Now, imagine you have a mold cavity designed for a specific size, but as the PP cools, it shrinks away from the mold walls. This creates a sort of suction effect.

Interesting.

That can make it incredibly difficult to release the product cleanly.

So it's almost like trying to pry a suction cup off a window.

Exactly.

It seems like you'd need a really steep release angle to overcome that clinginess.

You got it. A larger angle is generally needed for PP compared to, say, other plastics. If we don't compensate for that shrinkage, we risk the product getting stuck, warping, or even breaking during that release process.

And then you're right back to those costly production delays, damaged molds.

Yeah.

I'm already starting to see the ripple effect that one small detail can have on the entire manufacturing chain.

Oh, for sure, for sure. It really highlights the importance of understanding the properties of each material you're working with. And it's not just the shrinkage, Right. The melting point, the flexibility, how easily the molten plastic fl. All these things influence how we design the mold and calculate those crucial release angles.

It's a lot to keep in mind.

Yeah.

So we've got the material itself playing a role. But the research also mentioned the shape and size of the product being molded as, like, crucial factors. I think there was even an analogy about candles.

Ah, yes, the candle analogy. It's a simple way to visualize how the depth of a product can impact the release angle. Think about trying to get a tall, thin candle out of its mold. If you pull it straight up, there's a good chance it's going to snap. Right. But if you tilt it slightly as you hole, you're more likely to get it out in one piece.

Yeah, that makes perfect sense. So the deeper the product, the more important that angle becomes to prevent damage during release. But how do engineers actually calculate the ideal angle?

Right.

Is it a gut feeling, or is there a more, I guess, scientific approach?

Well, intuition definitely plays a role, especially for, you know, experienced mold designers. But there's also a formula that helps us get into the nitty gritty of those calculations. It takes into account the depth of the product, the amount the lifter moves, uses a little bit of trigonometry, and spits out the ideal angle.

Okay, I'm sensing a math lesson. Coming on. Walk us through it. How does this formula actually work?

It's not as intimidating as it sounds.

Okay, good.

The basic formula is tangent of the angle equals the lifter movement divided by the product depth.

Okay.

So let's say you have a cylindrical product that's, let's say 100 millimeters deep, and your lifter moves 5 millimeters to release it.

Yeah.

Plug those numbers into the formula, you get an angle of roughly 2.86 degrees.

Okay.

But here's the patch. In real world applications, we often need to bump that up a bit.

Right.

A 3 degree angle would be the minimum for a reliable release in this example.

So it's not just about, like, the raw numbers. Right. There's some practical experience and judgment involved too.

Yeah.

I guess those subtle adjustments can make all the difference between a smooth release in a stuck product.

Exactly. And when you start working with more intricate shapes, those calculations get even more complex.

Right.

We can't just rely on a simple formula anymore.

Yeah.

Imagine something like a multi part toy with curves and undercuts and interlocking pieces.

Sounds like a real head scratcher.

Yeah.

How do you even begin to approach something that intricate?

That's where our trusty friend CAD software comes in.

Yeah.

Computer Aided Design.

Okay.

It's become an indispensable tool for modern mold design.

Gotcha.

We can create a detailed 3D model of the product, rotate it, zoom in on specific areas, and really dissect the geometry.

Cool.

It's like having a virtual mold. Right. On our screens.

So you're basically mapping out all the potential trouble spots. Those areas where the product might cling to the mold during release.

Precisely. And once we've identified those critical surfaces, we can start breaking them down into simpler geometric shapes. Cones, cylinders, maybe even just flat planes.

Right.

Then we apply those release angle calculations to each individual section.

It's like solving a 3D puzzle.

That's a great way to put it.

Yeah.

Breaking the complex shape into manageable pieces. This approach lets us be much more precise, ensuring each section of the mold has the optimal release angle.

Okay.

And CAD software helps us visualize the entire process, minimizing the risk of errors or surprises down the line.

So it's like a really powerful tool.

Oh, absolutely.

To help mitigate risk.

For sure.

I'm starting to grasp the power of CAD in this process.

Yeah.

But let's be honest, there will still be situations where even with cad, those calculations get incredibly complex.

Absolutely. When you're dealing with really intricate designs, things can get challenging.

Right.

That's where Simulation software comes into the picture.

Okay.

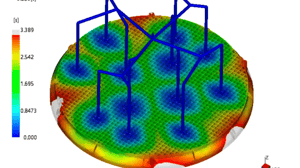

We can actually simulate the entire molding process virtually.

Wow.

Watch how the molten plastic fills the mold. See how it cools and solidifies, and even test the release process with different angles and lifter configurations.

Wow. So it's like having a crystal ball to preview the manufacturing process before it even happens.

You got it.

That's cool.

This allows us to identify potential issues early on, adjust designs, and experiment with different materials, all without the risk and expense of building a physical prototype.

Right.

It's really revolutionized how we approach mold design.

This is all starting to feel very high tech, but I imagine there's still a human element to it, right?

Oh, for sure.

It can't all be formulas and simulations.

You're absolutely right. Engineering and science provide the foundation, but designing a successful mold also involves a certain amount of intuition, experience, even artistry.

Okay. I'm curious about that.

Yeah.

What does the artistry of mold design look like?

It's about finding elegant solutions to complex challenges.

Okay.

For instance, sometimes we need to incorporate special features into the mold, like strategically placed vents to allow trapped air to escape or cooling channels to control the temperature distribution.

So you're thinking about things like that.

It's a delicate balancing act.

It sounds like there's a lot of problem solving involved.

Yeah.

Almost like a detective trying to anticipate every possible issue before it arises.

That's a great analogy.

Okay.

And beyond the technical aspects, there's also an element of visual design. Oh. The placement and shape of the parting lines where the two halves of the mold meet can impact the esthetics of the final product.

Right.

So we're not just thinking about function. We're also thinking about form as well.

So you're wearing multiple hats.

Right.

Engineer, scientist, and artist all rolled into one.

You could say that.

That's cool.

It's a multifaceted field that requires a broad range of skills and a keen eye for detail. And it's incredibly rewarding to see a design come to life knowing you've played a part in creating something both functional and beautiful.

This deep drive is really opening my eyes to the complexity behind something I used to take for granted.

Right.

It's amazing how much thought and expertise goes into those everyday plastic products we encounter everywhere.

It's easy to overlook the intricate processes that shape our world, but I think that's part of the beauty of it all. There's so much ingenuity hidden in plain sight.

I couldn't agree more.

Yeah.

Well, I feel like we've covered a lot of Ground. Here we've explored the importance of release angles, delved into the challenges of different materials and complex shapes, and even touched upon the artistry of mold design.

Yeah.

Is there anything else we should highlight before we wrap up our deep dive?

I think it's worth circling back to something we discussed earlier. The fact that injection molding is a constantly evolving field. New materials, new technologies, new design challenges are emerging all the time.

Yeah.

What might seem like cutting edge today could be outdated tomorrow.

That's a great point.

Yeah.

We were talking about bioplastics earlier. They seem to hold a lot of promise for sustainability, but I imagine they also present some unique hurdles for mold designers.

Absolutely. Bioplastics often have different melting points, shrinkage rates, and flow characteristics compared to conventional plastics.

Right.

So we're having to adapt our designs and techniques, pushing the boundaries of what's possible with injection molding.

It sounds like the whole field is in a constant state of innovation, trying to keep pace with these new materials and technologies.

Exactly. And it's not just about keeping up. It's about finding ways to leverage these advancements to create better, more sustainable and more efficient products.

Right.

Yeah.

I'm particularly intrigued by the intersection of injection molding and 3D printing. I know 3D printing is already making waves in manufacturing.

It is.

But how is it impacting the world of injection molding specifically?

Well, we're starting to see more hybrid approaches being used.

Okay.

Where injection molding is combined with 3D printing to achieve even more complex and intricate designs.

Interesting.

For example, we might use 3D printing to create a highly detailed mold insert.

Right.

Which is then incorporated into a traditional injection mold.

So it's like merging the best of both worlds.

Yeah.

Combining the speed and efficiency of injection molding with the design freedom and customization of 3D printing.

Precisely. It's opening up a whole new realm of possibilities for what we can create.

Right.

We can produce parts with intricate internal geometries, complex textures, and even embedded functionality that would have been impossible or prohibitively expensive with traditional methods.

It's mind boggling to think about what the future holds for injection molding.

Yeah, it is.

I have a feeling those little release angles are going to continue to play a crucial role as the technology evolves.

I wouldn't bet against it. You're such a fundamental part of the process.

Right.

Ensuring a smooth and efficient release for every product, no matter how complex or innovative the design. Yeah. So the next time you pick up a plastic product.

Right.

I encourage you to take a moment to appreciate the journey it Took to get there. All those careful calculations, the precise engineering, and yes, those crucial release angles that made it all possible.

It's a great reminder that even the most commonplace objects have a story to tell.

They do.

A story of ingenuity, design, and a touch of scientific magic, for sure. Well, on that note, I think we've reached the end of our deep dive.

It has been a pleasure exploring this fascinating topic with you.

Likewise.

Keep those minds curious and never stop learning.

Great advice. Thank you. It really is fascinating to think about all that innovation packed into those everyday objects we often take for granted.

Right.

We've gone from simple toys to complex machinery, bioplastics, even the fusion of 3D printing and injection molding. It seems like the possibilities are endless.

It really does.

But through it, all, those tiny release angles remain a constant.

Right.

A critical element in ensuring a smooth and successful manufacturing process.

It speaks to the fundamental principles of engineering, doesn't it? No matter how complex the technology becomes, certain core concepts remain essential. It's like building a house.

Right.

You might have all the latest gadgets and appliances, but without a solid foundation, it's all for naught.

That's a great analogy.

Yeah.

And I think it underscores the point that even as we push the boundaries of what's possible with injection molding, we can't lose sight of those fundamental principles.

Right.

It's that combination of cutting edge innovation and solid engineering that drives progress.

Precisely. It's a constant balancing act. Yeah. And it's what makes this field so dynamic and exciting. There's always something new to learn, a new challenge to tackle, a new frontier to explore.

Speaking of frontiers, I'm curious to know what are some of the biggest challenges facing the injection molding industry right now? Where are those frontiers leading us?

Well, sustainability is a major focus.

Okay.

We talked about bioplastics, but there's also a lot of research going into reducing waste.

Right.

Developing closed loop manufacturing systems and finding ways to recycle and reuse plastic materials more effectively.

Yeah.

It's a complex problem.

It is.

But the industry is taking it seriously.

That's encouraging to hear.

Yeah.

I know there's been a lot of concern about the environmental impact of plastic production.

Right.

So it's good to know that sustainability is at the forefront of innovation.

Absolutely.

Right.

And beyond the environmental concerns, there's also a growing emphasis on efficiency and automation. Industry 4.0, the so called smart factory is changing the landscape of manufacturing.

Right.

We're seeing more interconnected systems. Yeah. Data driven decision making and the integration of robotics and artificial intelligence into the production process.

So it's not just about the materials and the design. It's about optimizing the entire manufacturing ecosystem.

Exactly. And I think that's where the real breakthroughs will happen in the years to come.

Right.

We'll see smarter molds, more intelligent processes, and a deeper understanding of how all those elements interact to create a truly sustainable and efficient manufacturing system. System.

It's a thrilling time to be involved in this industry.

It is.

And I have a feeling we're only just scratching the surface of what's possible.

I think so too.

So as we wrap up this deep dive, what's one key takeaway you hope our listeners walk away with?

I'd say it's this. Next time you encounter a seemingly simple plastic product, take a moment to consider the journey it took to get there.

Okay.

From the initial design concept to the final release from the mold, there's a fascinating world of science and engineering and innovation at play.

Right.

And those tiny release angles, often hidden from view, are a testament to the ingenuity and precision that goes into creating the products we use every day.

It's a reminder that even the smallest details can have a profound impact. And it's a testament to the human spirit of creativity and problem solving that continues to shape our world.

Well said.

Well, on that note, I think we've reached the end of our deep dive into the world of injection molding and lifter release angles.

Right.

Thanks for joining us.

It's been a