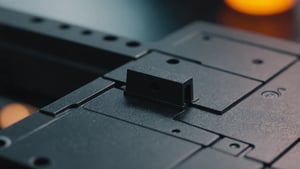

All right, so today we're diving deep into something that I know can be a real headache for anyone working with injection molding. Those annoying jet marks.

Definitely.

You know, those blemishes that can just ruin an otherwise perfectly smooth surface. We've got some really great resources that you all shared with us to help tackle this problem, and I'm really excited to have our expert here to break it all down.

It's great to be here. And you're absolutely right. Those jet marks, they might seem small.

Yeah.

But they can really make a big difference in the final product, both how it looks and how it works.

Sure. So you're trying to get rid of jet marks, and we're going to look at this problem from three different angles based on the stuff you sent us, how the mold itself is designed, what material you're using, and the molding process itself.

Okay, sounds good. Let's start with mold design, because that's really, like, the foundation for everything else. It's like building a house.

Yeah.

You got to get that foundation right, or you're going to have problems later.

That makes sense. So word specific design elements can actually cause or prevent jet marks.

One of the biggest things is the gate. That's where the melted plastic flows into the mold cavity.

Right.

And a standard gate can create the sudden surge of pressure as the material goes in.

I see.

And that can lead to jetting and those little imperfections.

So it's kind of like a traffic jam in a narrow doorway.

Exactly. Now imagine if we widened that doorway or even had multiple entry points. That's the idea behind things like overlapping gates or ear gates or fan gates. They all help spread out the flow more evenly and reduce that initial burst of pressure that causes those marks.

Interesting. So we're kind of smoothing out that initial flow of plastic. Are there any downsides to using those different gate designs?

There can be some trade offs. For example, overlapping gates.

Yeah.

They're really good at reducing sheer stress, which is the force that can actually make jet marks worse. But they might not be suitable for all types of materials. Some are really sensitive to that shearing.

Gotcha. So it's kind of about choosing the right tool for the job.

Yes, exactly. Now, ear gates, on the other hand, they're often used for thicker parts or for materials that don't flow as easily. They can direct that flow more precisely, but they can also increase the risk of air getting trapped if you're not careful with the design.

Ah, okay. I'm starting to see how much thought goes into this. What about the size of the gates and runners, does that matter too?

Absolutely. Think of it like plumbing. A bigger pipe lets water flow more freely with less pressure.

Right, Right.

Same idea here. Wider gates and runners, they reduce that resistance, and that leads to smoother, more controlled flow and fewer jet marks.

So we're easing the pressure, spreading it out a bit. What else should we think about when we're designing the mold?

Venting is crucial.

Venting.

These are like little channels that let gases escape during the injection process. If those gases get trapped, they can create pressure buildup, which can contribute to defects like jet marks.

That's kind of like those vents on a pressure cooker.

Exactly.

Letting steam out so it doesn't explode.

Exactly. Good vents make sure those gases get released smoothly so you don't have those pressure related issues.

Got it. So we've talked about gates and runners and vents.

Yeah.

Sounds like there's a lot of back and forth between the mold designers and the engineers to get this. All right.

You're absolutely right. It's a team effort to find that perfect balance.

Yeah.

Where the design works with the specific needs of the part and the material makes sense.

So the mold design, that's our foundation. But what about the building blocks themselves, the plastic materials? I imagine different plastics behave differently.

Yeah, you're absolutely right. Choosing the right material is just as important as the mold design when it comes to minimizing jet marks. One of the key things to look at is the fluidity of the plastic or how easily it flows under pressure.

Okay. So some plastics are more like water, flowing easily, while others are more like honey, thick and sticky.

That's a great analogy. Materials like polypropylene and polyethylene, they're known for their high fluidity.

Okay.

Which means they flow easily into the mold cavity, so you're less likely to get those jet marks.

And what about the less fluid plastics? What can we do with those?

Well, for those materials like abs that are a bit more resistant to flow, we might need to take some extra steps. One thing we can do is add lubricants to the plastic. Think of it like oiling a squeaky hinge.

Yeah.

These lubricants help the plastic molecules slide past each other more easily, which improves the overall flow and reduces that risk of jetting.

So we can actually tweak the material itself to make it more cooperative.

Some common lubricants they use in injection molding are fatty acids.

Okay.

Esters and metal stearates. But choosing the right lubricant is really important because it needs to work with the specific type of plastic you're using and the application you have in mind.

Right, right. Yeah. And while we want good flow, we can't forget about the other properties of the material. Right, right. We still need it to be strong.

Absolutely.

Heat resistant, and all that good stuff.

You are absolute. We need to make sure the material can do its job in the final product. So it's about finding that balance between good flow and good functionality.

All right, so we've got our mold design. We've picked our plastic. What's next? How do we actually get rid of those jet marks?

Now we got to look at the molding process itself, how we get that melted plastic into the mold. And you guessed it, there are a few key things we can adjust here to really minimize those blemishes.

Okay. So this is where things start to get really hands on. I'm ready. What's the first thing we should look at?

One of the most important things is the filling speed.

Filling speed.

How fast we inject that plastic into the mold. If we inject it too quickly, it can create turbulence and uneven flow.

Right.

And that can lead to jet marks.

So speed is important. How do we find that sweet spot? How fast is too fast?

The key is to control the filling speed curve. We want to start slowly.

Okay.

Let that initial wave of plastic flow through the gate at a nice, gentle speed to minimize those sudden changes in pressure. Then, once the plastic is flowing smoothly into the cavity, we can ramp up the speed and make sure it fills completely.

So it's like easing into it. A gentle start, and then hit the gas precisely.

And there are other process conditions we can adjust to. Things like mold temperature and melt temperature. Getting these right is crucial for smooth and consist consistent flow. If it's too cool, the plastic might solidify before it fills the cavity. If it's too hot, it could degrade or even burn.

So we're controlling the speed and the temperature. What else?

Injection pressure is another key parameter. Okay. If there's too much pressure, it can force the plastic in too quickly.

Right.

And cause jetting. But too little pressure.

Yeah.

And you might not fill the mold completely, or you could get what's called a short shot.

So it's a delicate balance. Finding that just right zone.

Exactly. And then there's the holding time.

Holding time.

That's after the cavity is filled.

Right.

We maintain the pressure.

Okay.

Just for a little bit.

Yeah.

To make sure all the little nooks and crannies are packed in properly so.

We'Re holding the pressure Just to make sure everything sets perfectly.

Exactly.

It seems like there's a lot of finesse involved in this.

There is. Luckily, modern injection molding machines have really advanced controls these days. So we can fine tune all these parameters super precisely.

That's good to know.

We can even program custom profiles for the filling speed, the temperature and pressure.

Right.

And find the best conditions for each specific part and material.

That's awesome. This is all so interesting. So we've talked about mold design, material selection, and now all these fine tuned process adjustments.

Yeah.

Is there anything else we need to think about to prevent those jet marks?

You know, there is something that often gets overlooked but can make a big difference is regular maintenance. Oh.

Keeping things clean and running smoothly.

Exactly. Even with the perfect mold design, the ideal material, and all the right process conditions.

Right.

Things can go wrong if the mold itself isn't well maintained.

Okay. So tell me, why is mold maintenance so important for preventing those jet marks?

Think of it like taking care of your car.

Okay.

Regular oil changes and checkups help prevent big problems later on. Right. Same with injection molds. Regular maintenance prevents wear and tear and keeps those mold surfaces nice and smooth. And that can prevent jet marks.

Okay. So mold maintenance, it's like preventative medicine for our injection molding process. But it has other benefits too, though, right?

You bet. Well maintained molds last longer.

Oh, right.

Which saves money on replacements.

That's good.

It reduces downtime and it keeps the quality consistent.

Love it. So what are some of the key things involved in that regular maintenance?

Well, regular cleaning is essential.

Okay.

Got to get rid of any residue or buildup that could affect the plastic flow.

Yeah.

Or create imperfections on the part.

Okay.

And regular inspections are just as important.

Inspections.

We got to catch any signs of wear and tear early on.

Right.

Small cracks, scratches, any damage that could mess up the quality of those parts.

Got it. So we're cleaning, we're inspecting. Anything else to keep those molds in tip top shape.

Lubrication is key.

Okay.

Just like your car's engine, keeping those moving parts of the mold properly lubricated keeps things running smoothly and reduces wear.

Yeah.

And then there's calibration.

Calibration.

Making sure everything is aligned and functioning as accurately as possible.

It's like a well oiled machine. Literally.

That's it. And one more thing that's really important is documentation and training.

Documentation and training.

Keeping detailed records of all those maintenance activities.

Okay.

Helps you track how the mold is doing over time. That way you know when to do more extensive repairs or even Replace it.

Right.

And proper training for the team makes sure everything is done correctly.

It's all about being proactive and paying attention to the details.

Precisely. That's how you keep your injection molding process running smoothly and get rid of those pesky jet marks.

This has been great. We've covered so much already. Mold design, material selection, all those process adjustments, and now how important regular maintenance is. It's clear that preventing jet marks, it's a whole process thing. You got to consider every step.

Absolutely. And while we've laid a good foundation, there's still more to explore. For example, have you ever thought about the connection between how fluid a material is and how much venting you need in the mold? Hmm.

That's an interesting thought. Yeah. I could see how those two things could be related. A thicker material might trap more gases. Exactly. So you need more venting.

It's something to think about as you keep working towards those perfect jetmark free parts.

This has been an incredible start.

Glad to hear it.

Where do we go from here?

Well, we've covered the basics.

Okay.

But there are even more advanced techniques for optimizing the process.

Oh, cool.

And taking your jet mark prevention to the next level. Let's dig into those next.

Awesome.

Welcome back. Before the break, we were talking about how crucial routine maintenance is to prevent jet marks.

Right. It's like keeping your whole injection molding process running smoothly. We talked about those essential tasks. Cleaning, inspecting, lubricating, and calibrating the molds.

Right.

But you also mentioned something else I found really interesting. The importance of documentation and training for the team.

Yes.

Can we dive a little deeper into that?

Absolutely. Good documentation is like keeping a detailed history of each mold. It helps you see how it's performing over time, spot recurring issues, and then you can make better decisions about repairs or when it might be time to replace a mold completely.

So it's not just about fixing problems as they come up. It's about actually anticipating them and addressing them before they become big headaches.

Exactly. And having a well trained maintenance team that's just as important. They need to know the ins and outs of each mold.

Right.

How to clean and inspect it properly, and how to do all those maintenance tasks the right way.

It's like having a pit crew for your injection molding process. A team of experts who know exactly how to keep everything running smoothly.

I like that analogy. And just like a pit crew, a well trained maintenance team helps minimize downtime and ensures your molds are always in top shape, ready to produce those perfect parts. You want okay.

This is all great information, but let's be honest. Sometimes even with the best plans, those jet marks can still show up. What do we do then? What other tools do we have to combat them?

But let's go back to those different gate designs we talked about earlier. Overlapping ear and fan gates.

Right. Those specially shaped entryways that help the plastic flow smoothly.

Exactly. But remember, it's not one size fits. All.

Right.

Each design has its pros and cons, and the best choice depends on a few different factors.

Like what? What kind of factors?

Well, the type of plastic is a big one. For example, overlapping gates.

Yeah.

They're good at reducing shear stress, but they might not be ideal for materials that are sensitive to that force.

Can you remind me quickly, what exactly is shear stress again?

Sure. It's basically the force that tries to make layers of material slide past each other. Think about spreading a deck of cards on a table.

Okay.

If you push the top card, the whole stack moves. But the cards also slide a little bit against each other.

Yeah.

That sliding is what causes shear stress.

Okay, that makes sense. So some materials can handle more shear stress than others.

Exactly. And some materials, like certain nylons, are quite sensitive to it.

I see.

So if you're using one of those materials, you might want to avoid overlapping gates.

Right.

And think about a different design, like an ear gate.

Okay. What are the benefits of using an ear gate, then?

They're often used for parts that are thicker.

Yeah.

Or for materials that don't flow as easily.

Okay.

They help direct the flow more precisely. But they do need to be carefully designed so you don't trap air.

Gotcha. And when would we use a fan gate?

Fan gates are designed to spread the flow out over a wider area.

Yeah.

Which can be really helpful for reducing jet marks on bigger parts.

Okay.

They basically split the flow into multiple smaller streams.

Right.

Which reduces the impact force of that plastic when it goes into the mold.

So it's all about finding the right gate design for the part and the material.

Exactly.

So the plastic flows in smoothly and evenly.

You got it. And sometimes just a small adjustment to the position of the gate can make a big difference.

Really?

Yeah. You want to make sure that first surge of plastic doesn't hit a large area directly, because that can cause those sudden changes in flow that lead to those jet marks.

So we're talking finesse and precision, even down to where the gate is placed.

Precisely. Speaking of precision, let's go back to those process adjustments. We talked about things like filling speed, mold temperature, and injection pressure.

Right.

There are ways to fine tune those parameters even more.

Oh, cool.

To optimize the flow and really minimize those jet marks.

I love fine tuning. Tell me more. What kind of techniques are we talking about?

Remember the filling speed curve?

Yeah. Starting slow and then speeding up once the plastic is clowing smoothly.

That's right. We can actually control that curve in more detail by adjusting the acceleration and deceleration rates. We can basically create a custom profile for that curve that's tailored to the specific part and material.

So it's like we're choreographing the flow of plastic.

Exactly. And we can do the same thing with mold temperature and injection pressure.

Okay.

We can create custom profiles that change those parameters over time to make sure the plastic is flowing consistently during the whole molding cycle.

So we're moving beyond those basic adjustments and really dialing things in to get the perfect flow.

Exactly. And luckily, modern injection molding machines give us the tools to do that.

That's great.

We can monitor and control these parameters in real time.

Wow.

And make tiny adjustments on the fly to get those optimal conditions throughout the whole process.

It's amazing. Like a conductor leading an orchestra, making sure every instrument is playing in harmony.

Great analogy. And just like a well conducted orchestra makes beautiful music.

Yeah.

A well controlled injection molding process makes perfect parts.

Right.

Without those jet marks.

It's pretty cool how much science and precision goes into making something that seems so simple.

I know, right?

Like a little plastic part.

It's amazing. But even with all this advanced technology and fine tuning, sometimes we still get those stubborn jet marks.

Okay, so what do we do then? What are our options?

Well, we can actually tweak the material itself to improve how it flows. One way to do that is by adding something called a flow modifier.

A flow modifier? What's that?

It's a special additive that can be mixed in with the plastic.

Okay.

To reduce its viscosity.

Right.

And help it flow better.

So it's like giving those sticky plastics a little boost.

Exactly.

To make them flow more smoothly.

That's it. And there are different kinds of flow modifiers out there.

Oh, okay.

Each one designed to tackle specific properties.

I see.

Some help reduce the melt viscosity, which makes the plastic easier to inject. Others improve melt strength to stop it from sagging or distorting during molding.

Okay.

And some even make the surface finish better, which can help hide those jet marks.

Wow. So many options. It's incredible how much control we have over these materials.

It really is. And the science behind modifying Polymers is always advancing.

Yeah.

So there are always new and better ways to fine tune materials for different uses.

This has been super helpful. We've covered so much ground, from the basics of mold design, material selection and process adjustments to these more advanced techniques for fine tuning things and even modifying the materials themselves. It's clear that preventing jet marks is tricky.

It can be.

But it's definitely something we could overcome with the right knowledge and a little ingenuity.

That's the spirit. And as we go deeper into this, there's another really interesting aspect I think we should talk about.

Okay.

One that can have a big impact on quality but is often overlooked.

Okay. I'm all ears. Tell me more.

It's the power of mold flow analysis.

Mold flow analysis? What is that?

It's this really cool tool that lets us simulate how the plastic will flow inside the mold.

Oh, wow.

Before we even build the mold.

So we can actually see how the plastic is going to behave.

Exactly.

Before we even start the injection process.

That's right. We use special software.

Okay.

To create a virtual model of the mold. And then we run simulations to see how the plastic will flow, where it might run into resistance, and how it'll fill the cavity. It's like getting a sneak peek into the future of your molding process.

It's like having a crystal ball for injection molding.

You got it. And the information we get from those simulations is super valuable.

Okay. Give me some examples. How does this mold flow analysis actually help us prevent jet marks?

Say you're designing a new part.

Yeah.

And you're trying to decide where the best place for the gate is. Mold flow analysis can show you how the plastic will flow from different gate positions.

Okay.

So you can choose the one that creates the smoothest flow.

Right.

And minimizes the chances of those jet marks.

So we can try out different design options virtually before we actually build the mold.

Exactly. And it goes beyond just the gate.

Okay.

We can use mold flow analysis to optimize other design features too, like the size and shape of the runners. The placement of the vents.

Yeah.

Even the thickness of the part itself.

So we can tweak the whole mold design.

Exactly.

Get that perfect flow.

You got it. And mold flow analysis can also help us spot potential problems in the design at places where the plastic might get stuck or where there might be too much pressure.

Wow. It's like we're doing a virtual inspection of the mold before we even build it.

And by fixing those potential problems in the design phase, we can stop them from becoming real problems during Production, and that can save a lot, lot of time and money and frustration.

Mold flow analysis sounds like a game changer. It's like having a superpower for injection molding.

It's a powerful tool for sure.

Yeah.

And as this technology gets better and better.

Right.

We're discovering even more ways to use it to optimize our processes.

This has been such a cool journey. We started with the basics of mold design, material selection, and process adjustments.

Right.

And now we're exploring these advanced techniques like fine tuning parameters. Yeah. Modifying the material and this awesome mold flow analysis. Preventing jet marks really takes a multi pronged approach.

You're right.

And a real desire to always be improving.

Couldn't have said it better myself.

Yeah.

And as we continue this journey, there's one last thing I want to touch on.

Okay.

Something that's kind of obvious but often overlooked.

Okay. I'm ready for one last piece of wisdom. What is it?

Think about the role of the operator in all of this.

Oh, that's a great point.

Yeah.

We've talked about the machine, the mold, the material, the process, but it's the operator who actually makes it all happen, Right?

Exactly. The operator is like the conductor of the orchestra, the one who's actually running the show. Their skill, knowledge, and attention to detail can have a huge impact on how good the parts are.

So even if we have the perfect mold, the perfect material, and a fantastic machine.

Right.

We still need a skilled operator to make sure everything runs smoothly.

Absolutely. They need to understand how the machine works, the properties of the material, the details of the molding process.

Right.

They need to be able to monitor everything, make adjustments when needed, and fix any problems that pop up.

It's like having a great recipe, but you still need a good cook to make the meal delicious. You need that expertise to put it all together precisely.

And just like a great chef can make. Amazing. A skilled operator can make perfect parts.

This whole deep dive has been so insightful. We started by looking at mold design and material selection. Then we went into these more advanced techniques like mold flow analysis, and we even talked about how important the machine itself is. And now we're recognizing that human element.

Yeah.

The role of the operator in making those perfect jet mark free parts.

It's all connected.

It's been amazing exploring all of this with you.

The pleasure is all mine. And remember, preventing jet marks is a journey.

Yeah.

It's about constantly learning, experimenting, and finding ways to improve.

Definitely. So to all our listeners out there who are working towards those perfect Jetmark free parts. Yeah. Keep Learning keep those molds clean.

Yes.

And those machines humming. And don't forget to give those skilled operators a high five.

Absolutely.

They're the real heroes of injection molding.

Couldn't agree more. Until next time. Happy molding.

Welcome back, everyone. So before the break, we were talking about how even the injection molding machine itself can be a factor in those jet marks.

Right.

Something, I have to admit, I hadn't really thought about much before.

It's easy to overlook. We often get so focused on the mold and the process that we kind of forget about the machine doing all the work. It's like having a fantastic chef giving them dull knives and a crummy oven.

I like that. So what should we be looking at specifically?

Yeah.

When it comes to the injection molding machine, how can it impact those jet marks?

One of the biggest things is the precision of the injection unit.

Okay.

That's the part of the machine that melts the plastic and shoots it into the mold.

Right.

If that unit isn't precise.

Yeah.

You can get inconsistent shot sizes, and the mold cavity won't fill evenly. And that's a recipe for jet marks.

So it's all about consistency.

Exactly.

And control. During that injection process, we need to.

Make sure that injection unit is delivering the right amount of plastic.

Right.

At the right pressure and temperature.

Yeah.

Every single time.

Makes sense. So meticulous maintenance.

Yes.

Making sure everything's working properly.

Absolutely.

And regular calibration are key.

It's like keeping those chef's knives sharp.

Right.

And that oven temperature steady.

Exactly. Yeah. What about clamping force? Does that matter too?

Oh, absolutely. Right. Clamping force is what holds those two halves of mold together.

Right.

During injection.

Yeah.

If the force isn't strong enough, the mold can actually separate a little bit.

Wow.

And some plastic can leak out.

I didn't realize that.

Yeah. And that creates flash. And it can also lead to uneven filling, and, you guessed it, more jetting.

So we really need to make sure those mold halves are clamped together tight.

Exactly. And it's not just about the amount of force. It's about making sure that force stays consistent.

Yeah.

Through the whole molding cycle. If it fluctuates, you can get variations in the dimensions of the part.

Right.

And, well, you know what that means.

Jet marks. Okay. So precision of the injection unit.

Yes.

And consistent clamping force are important.

Right.

Anything else about the machine itself that can affect jet marks?

The overall stability of the machine and how much wear and tear it has are definitely factors.

How so?

Think about it. If the Machine is vibrating a lot. Or if there's too much play in the moving parts, it's going to affect how accurate and repeatable the molding process is.

It's like trying to write neatly on a shaky table. You're never going to get those crisp lines.

Exactly. And over time, as parts wear down, they can start to create inconsistencies.

Right.

So those regular checkups and maintenance are really important to keep the machine running smoothly and accurately.

It's like giving that injection molding machine a tune up. Oil changes, belt adjustments, all the little things to keep it in top shape.

That's a great way to put it. And the best part is nowadays we have these high tech ways to keep tabs on how well those injection molding machines are doing.

Oh, cool.

Sensors and data analysis can help us track those key performance indicators.

Yeah.

So we can catch potential problems before they become big issues.

So it's like a fitness tracker for your injection molding machine.

I like that. And all that data helps us make smart decisions about when to schedule maintenance.

Right.

How to tweak the process, and even when it might be time to upgrade the whole machine.

This deep dive has been incredible.

I'm glad you think so.

We've covered so much ground. Mold design, material selection.

Right.

Tweaking those process adjustments.

Yeah.

And now we're even looking at the injection molding machine itself.

Absolutely.

It really shows that if you want to get rid of those jet marks, you have to look at the whole process.

You got it.

Every single element.

It's all connected.

And you have to always be looking for ways to improve.

That's the key. And as we wrap things up here, there's one last thought I want to leave everyone with.

Okay.

It's something that's pretty obvious but often overlooked.

I'm ready. Hit me with it.

Think about the role of the operator in all of this.

Oh, that's a good point. We've talked about the machine, the mold, the material, the process.

Right.

But it's the operator who's actually running the show.

That's right. The operator is like the captain of the ship. Their skill, their knowledge, their attention to detail can really make or break the quality of the parts.

So even with all the fancy equipment and the perfect setup, we still need a skilled operator to make sure it all comes together.

Absolutely. They need to understand the machine inside and out. They need to know the material they're working with, and they have to really understand the whole molding process.

It's like having all the ingredients for a great cake. Yeah, but you still need a good baker to actually make it.

Exactly. A skilled operator can take all those elements and create those perfect Jetmark free parts.

This deep dive has been amazing. We've learned so much. Mold, design, material, selection.

It's been fun.

All those advanced techniques and even the role of machine and the operator, all.

Part of the puzzle.

It really is.

Yeah.

So to everyone out there, keep learning. Keep experimenting.

Yes. Keep those molds clean and keep those machines running until next time. Happy molding,