All right, let's dive right in, shall we? Today we're tackling a topic that's kind of hidden but super important. Making those injection molds cool down faster. You know, the ones that make a ton of the stuff we use every day.

Yeah, it's pretty fascinating stuff, actually.

We've got all sorts of research papers and expert opinions to dig into, all about making this process faster, better, and capable of making even, well, better products.

It might not sound like the most exciting thing at first, but trust me, the engineering behind it, it's pretty amazing. We're talking about controlling temperature and flow, using different materials, all to get those really impressive results.

You know, one of the papers we looked at had this great analogy. They were talking about this project where they optimized the cooling, and it was like, as they put it, night turning in today for their production line. Fewer defects, much faster turnaround. Pretty impressive stuff.

Yeah. Yeah, exactly. It's amazing how much of a difference it can make.

But before we jump into the really complex techniques, I'm kind of curious. What's the big deal about cooling in the first place? Why is it so important?

Well, it's not just about speed, although, you know, that's a huge factor, of course. But when you inject that molten plastic into a mold, it's got to cool down and solidify in a really controlled way. And if that process isn't absolutely perfect, well, you run into a lot of problems.

What kind of problems?

Warping parts, shrinking unevenly, Even internal stresses that can weaken the final product. It's really important to get it right.

So it's kind of like baking a cake.

Yeah.

You know, you can have the best recipe in the world, but if you don't cool it down properly, it'll sink in the middle or crack.

That's a great analogy. Yeah, exactly like that. It's all about controlling that cooling process to make sure the final product comes out perfectly.

And just like with baking, I guess the right cooling method depends on what you're making.

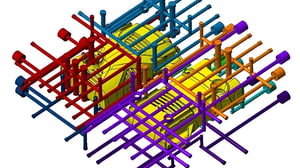

Absolutely. And in injection molding, a huge part of that comes down to how those cooling channels, those are the pathways for the coolant, are designed within the mold itself. It's kind of like strategically placing pipes around a hot engine.

Oh. To make sure everything cools evenly.

Yeah, efficiently and evenly. That's the key.

And the sources we've got really get into the nitty gritty of this. Talking a lot about the layout of those channels, I was surprised to learn that symmetry plays a big role. Why is that so important?

Well, Imagine you're trying to cool down, let's say a simple cylinder. If your cooling channels are placed symmetrically around it, the heat can dissipate nice and evenly. This prevents warping and makes sure all your parts come out the exact same size. It might seem kind of basic, but it's a fundamental principle, Right?

Right. It makes sense. And then it gets even more interesting when they start talking about the size of those channels. Some of the sources seem pretty excited about, you know, going bigger with those channels to speed things up. What's the logic there?

Well, larger channels let more coolant flow through, obviously, which means they can pull that heat away from the mold much faster. But. And there's always a but. If you make those channels too big, you risk weakening the structure of the mold itself.

Oh, I see.

Especially when you think about all the pressure involved in injection molding, you could end up with a mold that, well, cracks or even fails completely.

So it's not just about maximizing flow. It's finding that sweet spot between cooling power and making sure the mold can handle it all.

Exactly. It's finding that balance. And that's where things get really interesting, because the solution isn't always as simple as making everything bigger. You know, for example, when you're dealing with products that have really thick walls, the whole cooling challenge becomes even more complex.

Okay, so why is that? What makes cooling thicker parts so tricky?

Well, think about it. If you only have those cooling channels on the outside of a thick piece, the outer layers are going to solidify much faster than the core, and that creates internal stresses, which can lead to warping or even cracking as the inner part finally cools down.

Oh, so it's like the cake analogy again. If the outside cools too quickly, the inside might still be all gooey and the whole thing's a mess.

Precisely. It's the same concept. And to overcome this, engineers have developed, well, some really clever techniques.

Yeah, what kind of techniques?

One of the most effective is something called multilayer cooling. Instead of just having channels on the surface, you create multiple layers, layers of channels that run throughout the entire mold.

Ah. So it's like having this network of cooling pipes reaching every single part of the mold, even those super thick sections, making sure everything cools down at a consistent rate.

Exactly. Multilayer cooling lets you target different areas with different cooling rates, preventing warping in those thick parts that would normally cool unevenly. It's a total game changer. It makes sure those complex, thick components are strong and reliable.

This is really making me realize just how Much engineering goes into something that seems, you know, pretty straightforward on the surface. You wouldn't think cooling plastic would be so involved.

It's a very specialized field, and as you dig deeper, you start to see just how many variables there are that affect the final product. And it's not just the channels themselves. It's also about what's flowing through them.

Right? Yeah. The sources mention that choosing the right cooling medium can have a big impact on how efficient the whole process is. I'm guessing it's not just using plain old water anymore, is it?

Water is still the most common. Yeah, and for good reason. It's readily available and it can absorb a lot of heat. But in some cases, you really do need something a bit more specialized. Some materials don't react well with water, or they need super precise temperature control to avoid defects.

So it's about choosing the right tool for the job. Like, sometimes you just need a hammer, and other times you need a high powered laser.

Exactly. That's a great way to put it. Some manufacturers even use things like special coolants or even liquid nitrogen when they need extremely fast cooling for specific applications.

Liquid nitrogen. That sounds pretty intense. Is that, like, the super weapon of the cooling world?

It definitely is. But even when you're using those more common coolants, controlling the temperature and flow rate is crucial. One of the sources talks about a project where they ended up causing surface defects because they were using coolant that was too cold.

Wait, too cold? I thought the goal is to cool things down as quickly as possible.

It does seem counterintuitive. I know, but if there's too much of a temperature difference, you can actually shock the surface of the part, cause it to crack or deform. It's really all about finding that perfect balance where the cooling rate works for the material and the complexity of the part.

Wow. So even something as seemingly simple as the coolant temperature can make or break the final product. That's pretty incredible. It sounds like there's a real art to getting this right.

Oh, there definitely is. And we haven't even touched on the materials used to make the molds themselves. They play a huge role in how efficiently the heat is transferred away from the part.

That's right. The sources were really highlighting materials like copper alloys and high thermal conductivity steels. They sound like something out of a science fiction movie. But I guess the real question is, how do these fancy materials actually improve the process?

Well, that's a great question and one we'll dive into right after this. Stay with us.

So before we went to break. We were talking about, like, super materials for making these injection molds. You're about to explain how things like copper alloys actually make a difference when it comes to cooling.

Well, it really comes down to thermal conductivity. How quickly can the material move heat away? You know, traditional mold steels, they're okay, but these advanced materials, it's like they're on the fast track for getting rid of that heat.

Oh, yeah. The sources had a really cool analogy for beryllium copper.

Oh, yeah? What was that?

They described it as, like, a small engine that speeds up the transfer of heat. I mean, that's a pretty awesome image, right?

Yeah, it is. Beryllium copper is. It's pretty incredible stuff. Its thermal conductivity is so high, it just pulls that heat away from the part incredibly quickly. The downside is that it's not as strong as steel, and it can be a bit more expensive, of course.

Oh, that makes sense.

So you usually use it very strategically in those specific areas of the mold where you absolute that super fast cooling.

So it's like a turbo boost for cooling, just where you need it most.

Yeah, exactly. You got it. And then you have those high thermal conductivity steels. They're kind of in the middle.

Oh, how so?

They offer a really good balance. They're not quite as conductive as the copper alloys, but they're much stronger, which means you can use them in a lot more situations. You get that boost in cooling, but you don't have to worry about the mold, you know, falling apart.

So, again, it's all about finding the right material for the job, considering both how fast you need to cool things down and, well, how tough the mold needs to be.

Exactly. It's all about finding the right tool for the job. And that brings us to another really fascinating aspect of all this. Coatings. Some of the sources highlight some really cool options, like ceramic and diamond, like carbon coatings. And these coatings, they can actually help dissipate the heat even faster, and they protect the mold from wear and tear too.

I'm picturing it, like, giving the mold this suit of armor, you know? But this armor also helps to get rid of heat even faster. What's the science behind how these coatings actually work?

Well, it's all about the surface properties. These coatings change how the mold radiates heat. They make it much more efficient, and they also create this barrier that reduces friction and wear, which is super important when you're working with molds that have a lot of fine details and really.

Tight tolerances so it's like a double win. Faster cooling, and the mold lasts longer. But we've talked a lot about, you know, the physical stuff, the channels and the materials, the coatings. What about the actual process of controlling the cooling?

Yeah, that's where the real. Well, the real art comes in, I guess you could say. It's not just about having a good cooling system. It's about managing it, you know, actively managing it. Throughout that whole injection molding process, one.

Of the sources we looked at was really emphasizing this point. They were talking about how important it is to monitor and control things like the flow rate and the temperature of the coolant. It sounds like it's a lot more involved than just setting a thermostat and walking away.

Absolutely. These modern injection molding machines, they're incredibly sophisticated. They've got sensors that keep track of temperatures inside the mold, They've got flow meters for the coolant, and they've got all this fancy software that can analyze all of that data and make adjustments in real time to keep everything running smoothly and make sure you get really consistent, high quality parts.

So it's kind of like having a team of experts constantly watching over the whole process, making sure everything's perfect.

That's a pretty good analogy. And it gets even more advanced when you start talking about techniques like variable flow rate cooling. Instead of having that constant flow of coolant, you can actually change it in different parts of the mold depending on how much cooling each area needs.

So if you have a section with thicker walls, you might crank up the flow rate there just to make sure it cools down at the same pace as a thinner section.

Exactly. It's all about that level of precision.

Yeah.

And then you have pulsed cooling, which is even more interesting.

Oh, yeah, I remember that one. They were describing it like, almost like a heartbeat for the mold. How does that actually work?

It's kind of cool. It basically involves switching between high and low flow rates, or even stopping the flow completely for a short time. And this pulsing action, it helps distribute the heat more evenly in the mold, so you get a much more consistent product, and it can even improve the strength of the final part.

Wow. It's like this carefully choreographed dance between temperature and flow. It's so much more complex than I ever imagined.

And we've only just scratched the surface here. There's a whole field of engineering dedicated to this stuff, and it's constantly evolving. There are always new technologies coming out, like conformal cooling channels. They're really pushing the boundaries of what's Possible conformal cooling.

That was one of those terms that sounded super high tech.

Yeah.

What makes it so different from the traditional channels?

Well, think about how traditional channels are made. It's basically drilling straight holes into the mold, right?

Yeah.

And that works great for simple shapes, but when you start dealing with really complex parts with lots of curves and angles, those straight channels, they can't always get to all the areas that need to be cooled down.

Oh, so you end up with these hotspots that can mess up the whole process.

Exactly. And that's where conformal cooling comes in. These channels, they actually follow the shape of the part, no matter how complex it is, they can twist and turn and branch out to deliver that cooling exactly where it's needed.

It's like giving the mold its own custom fitted cooling system. But how do you even make channels that complex?

That's where 3D printing comes in. Additive manufacturing. It's a game changer for designing molds. It lets you create these incredibly intricate cooling channels that you could never make with traditional methods.

So we're talking about molds with these internal channels that look like. Like a crazy roller coaster?

Pretty much. And the best part is 3D printing lets you create these designs without adding a ton of cost or extra time to making the mold.

So it's like you're unlocking this whole new level of control.

It really is a pretty exciting development, and it's leading to some really incredible innovations in injection molding. But it's important to remember that all these techniques we've been talking about, from the fancy materials to the sophisticated cooling strategies, they're all tools. And the key is knowing when to use the right tool.

So it's not just about throwing all the latest technology at the problem. It's about understanding what you need to achieve and choosing the best approach for the job.

Exactly. There's no one size fits all solution when it comes to optimizing injection mold cooling. It's about finding the right balance between efficiency, quality, and keeping costs in check. And that's what makes it such a fascinating field.

This has been a pretty amazing deep dive so far. We've gone from the basics of how to design cooling channels to the cutting edge of 3D printing and all this super advanced stuff. But I think it's important to step back for a minute and ask, why does all this even matter? You know, what's the big picture here?

Well, it's a great question. And at the end of the day, optimizing injection mold cooling is really about, you know, pushing the boundaries of what's possible. By making things faster, we can produce more stuff at a lower cost. That makes things more accessible to everybody. And by making the products better, things last longer, they work better, and they have less of an impact on the environment.

So it's about making things better, faster and greener.

Exactly. And think about something like the medical industry. The ability to make those really complex medical devices quickly and accurately. I mean, that's been huge for healthcare, life saving innovations. And it's all thanks to the advanced advancements in injection molding.

It's not just healthcare, it's everything. Consumer electronics, car parts, renewable energy. Optimized injection molding is everywhere. It's shaping the world around us.

And as we're all becoming more aware of the environment, making things in a way that's efficient and doesn't waste a bunch of resources, well, that's just going to become even more important. That's where optimizing injection mold cooling can have a really big impact. By using less energy, creating less waste, and making products that are built to last, we're actually contributing to a more sustainable future.

It's a good reminder that engineering isn't just about, like, cool gadgets and inventions. It's about using those things to solve real problems and make the world a better place.

Absolutely. Well said. And as we wrap up this deep dive, I hope our listeners are feeling kind of excited about the future of manufacturing. It's an industry that's constantly evolving and there's so much potential there.

It's been a really fun journey exploring this topic with you. And for everyone listening, we encourage you to keep learning, exploring and asking questions. The world of manufacturing is full of amazing challenges and incredible innovations. Who knows, maybe one of you listening will be the one to come up with the next big breakthrough in injection mold cooling.

Yeah, I wouldn't be surprised. There's a lot of bright minds out there.

Thanks for joining us on this deep dive, everyone. We'll be back next time with another fascinating look at the world around us. Until then, keep diving deep. So we were talking about how important data and monitoring are when it comes to, well, getting the most out of injection mold cooling. I'm really curious to dig into that a bit more.

Yeah, it's, it's not enough to just, you know, design a good system. You got to make sure it's actually working the way you want it to throughout the whole process. It's kind of like having, you know, a really fancy oven, but never actually checking the temperature right.

You might end up burning everything Exactly.

You could end up with some pretty inconsistent results.

So how do you actually, like, monitor and control something as complex as this in real time?

Well, the good news is that these modern injection molding machines, they're. They're really smart. They have all sorts of sensors built right in.

Oh, what kind of sensors?

Temperature sensors right in the mold. Flow meters that track the coolant. And they even have software that analyzes all that data and can adjust things on the fly.

So it's like having, like a tiny team of engineers inside the mold making sure everything is running perfectly.

Yeah, it's pretty amazing, this level of monitoring and control. It's. It's really important for consistency and for catching any potential problems early on, you know, before they become big defects.

Oh, can you give us an example?

Sure. Like, let's say a sensor detects a temperature spike. The system can automatically adjust the flow of the coolant to compensate for that. It's all about keeping things balanced.

That's really cool. It seems like all this data is taking things to a whole new level.

Oh, absolutely. And this is really just the beginning. You know, as sensors and data analysis get even more sophisticated, we'll be able to fine tune these processes even more. We'll be able to make even better products and make them faster, too.

This whole deep dive has been really eye opening. You know, we've gone from basic cooling channels to 3D printing and all this smart monitoring. It's amazing. But I think it's important to step back for a second and ask, why does all this matter? What's the big takeaway here?

Yeah, it's a good question. At the end of the day, optimizing injection mold cooling, it's. It's about pushing the limits of what's possible. If we can make the process faster, we can produce more things and we can do it more cheaply, which makes, you know, makes products more affordable and accessible to more people. And if we can make the products themselves better, well, they'll last longer, they'll perform better, and they'll have less of an impact on the planet.

So about better, faster and more sustainable, all those good things.

Exactly. Think about, for example, the medical industry being able to make those really complex medical devices and being able to do it quickly and precisely. I mean, that's revolutionized healthcare. We're talking about innovations that are saving lives. And it's all thanks to the advancements in injection molding.

And it's not just medical. It's. It's everything. Our phones, our cars, renewable energy. It's everywhere.

And you know, as people are becoming more and more concerned about the environment being able to manufacture things efficiently without wasting a lot of resources, well, that's just going to get more and more important. And that's where optimizing injection mold cooling can really make a difference. Less energy, less waste, and products that are designed to last longer. It all adds up.

It's a good reminder that engineering, you know, it's not just about coming up with fancy gadgets. It's about solving real world problems and making things better.

Well said. I couldn't agree more. And as we wrap up this deep dive, I hope our listeners are feeling a little bit inspired by what we've talked about. There's so much potential in manufacturing. It's really an exciting field.

It's been fantastic exploring all this with you. And to all our listeners out there, keep learning, keep exploring, keep asking those questions. You never know, maybe you'll be the one to come up with the next big breakthrough in injection mold cooling.

I wouldn't be surprised. There's a lot of smart people out there.

That's right. Well, thanks for joining us, everyone. We'll be back next time with another exciting deep dive. Until then, stay