Expert Injection Mold & Molding Solutions from MoldAll

Request a Quote

Project Showcase

Your Trusted Partner for Injection Mold and Molding Solutions

Services

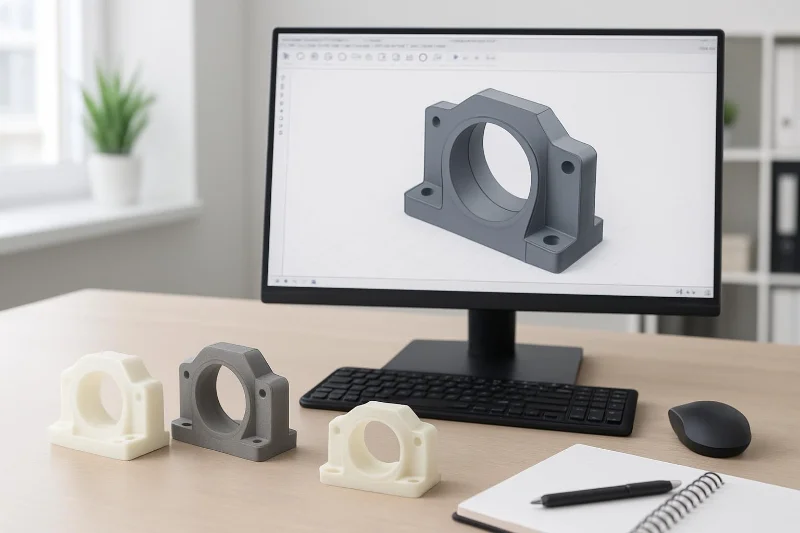

Rapid Prototyping

- Parts in 1-5 Days

- Functional Testing

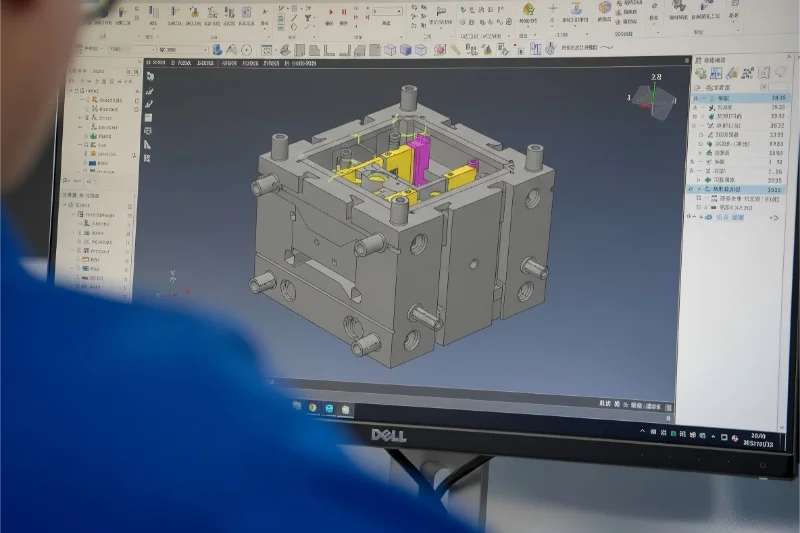

Mold Design Service

- Advanced Mold Flow Analysis

- DFM Feedback within 24h

Mold Making & Tooling

- 100+ Molds / Month

- High Speed CNC Machines

Injection Molding

- 30T to 1850T Press Capacity

- Overmolding & Insert Molding

Post-Processing

- Pad Printing & Painting

- Ultrasonic Welding

Product Assembly

- Box-Build Assembly

- Supply Chain Management

Our Capabilities

Electronics

Automotive

Medical

Irrigation

Robotics

Industrial

How to work with us

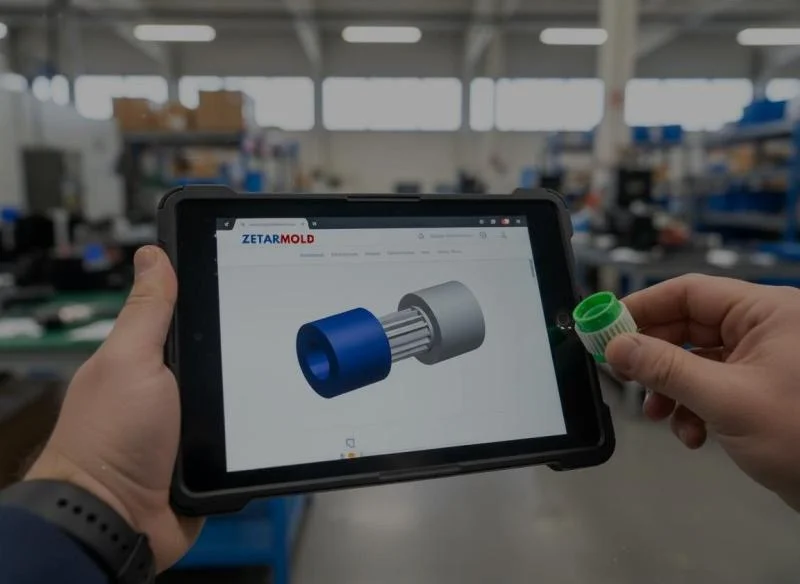

Upload Your Design

Get Quote with DFM

Mold Design & Fabrication

Start Part Production

Post-Processing

Quality Check & Shipment

About us

10+ Years of

Experience

Frequently Asked Questions

What information is needed for an immediate manufacturing quote?

To start your quote and DFM review instantly, we require your 3D CAD files (STEP/IGES), preliminary material specifications (or required properties), and the estimated annual production volume (EAU). Providing tolerance callouts is also highly beneficial.

How does your team assist us if our initial design has potential molding issues (DFM)?

Our engineering team conducts a thorough Design for Manufacturing (DFM) analysis on every submitted design. We identify and provide actionable feedback on areas like draft angles, wall thickness variations, and potential sink marks before mold production begins, saving you time and cost on revisions.

How do you guarantee tight dimensional tolerances and part consistency?

We ensure precision through controlled environment manufacturing and rigorous in-process quality checks (CMM/Optical). We guarantee the final parts will meet the agreed-upon specifications defined in the initial Project Quality Plan (PQP) we develop with you.

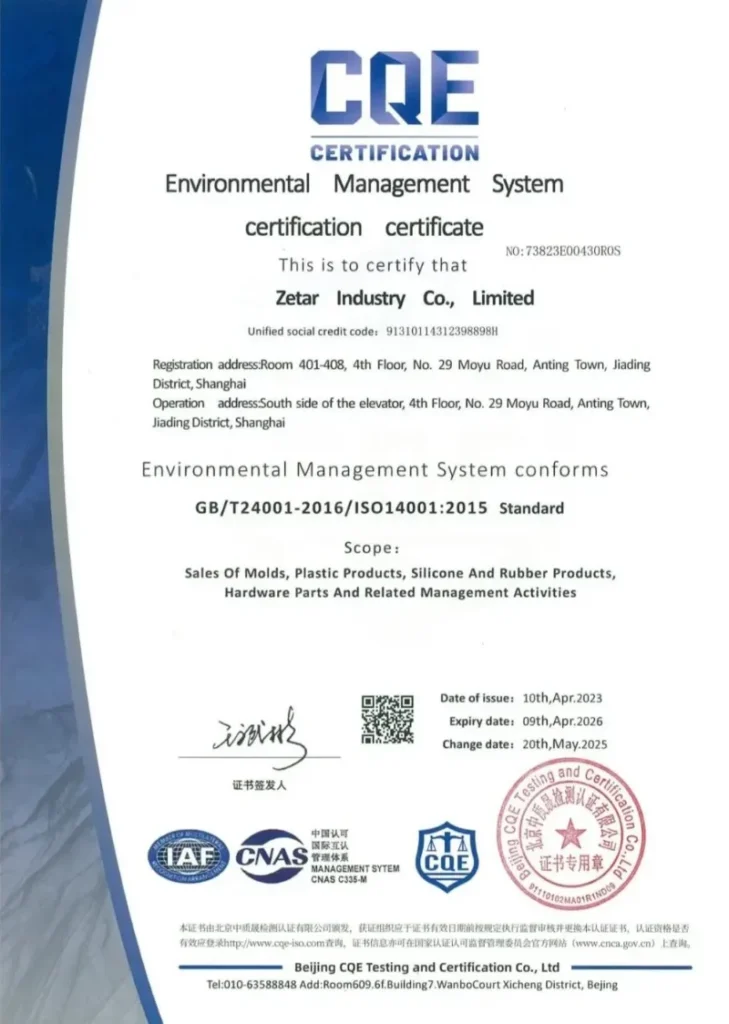

Quality Assurance